Product Details

Categories: Imaging Solutions

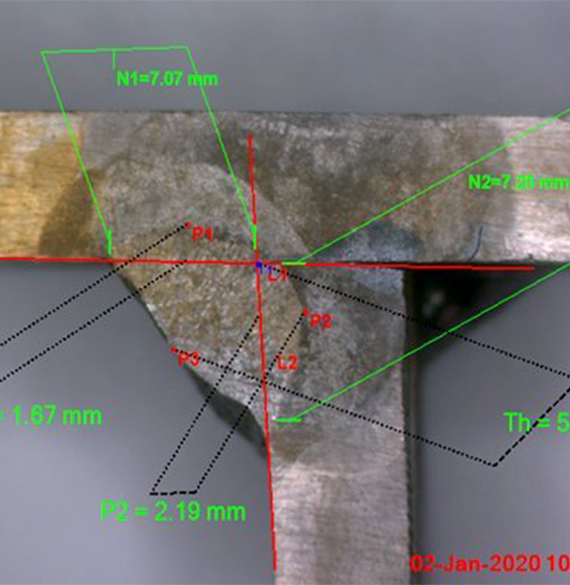

QS Metrology brings you the most advanced system for Weld Penetration Inspection - WeldEYE® from its stable. WeldEYE is our registered trademark. This system is the result of our long experience in Weld quality inspection, weld penetration testing and our interactions with automotive industry. Our system has features which are unmatched anywhere. This system can be used to measure all dimensional measurements (2D) like length, distance between, angle, radius, diameter, area etc.

Features