Product Details

Categories: Coating Thickness Gages

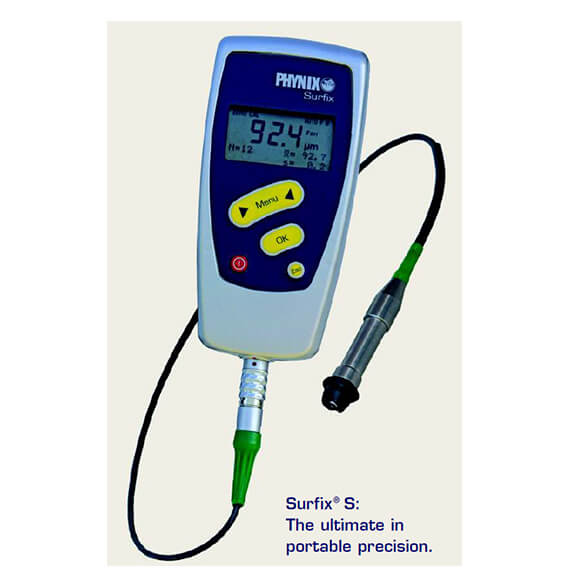

Our Surfix® S is a universal device and can be operated with various probes. Due to the our selection of interchangeable probes it offers a wide range of measurement applications. The option to store and transfer the measured data, the easy handling and the high accuracy make it the universal measurement gauge. The device is designed for tough operations in the field as well as in laboratories.

Surfix S comes in 2 configurations:

Surfix® S and

Surfix® S basic:no memory, statistics, limits, IR-interface

FN 0.2

FN 1.5, F 1.5, N 1.5, FN 1.5/90

FN 3.5, F3.5

F10