Contourecord 1600G

Contourecord 1600G

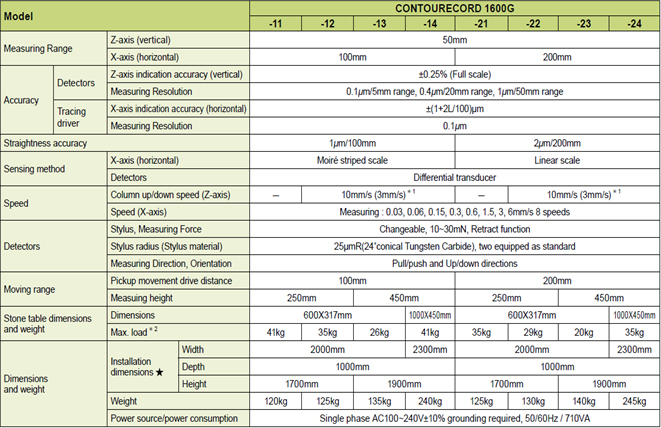

Flexible CNC measuring station for contour measurements. The instrument is designed to measure any intricate profile in a 2 dimensional format. The measured profile can be post-processed in the advanced ACCTee software to analyze the profile and extract dimensional details.

ACCTee contour profile meausurment and analysis

- Work trace function.

- Stylus calibration wizard.

- Peak and valley function.

- Calibration alarm.

- Master ball calibration function (patented).

- Pitch calculation function.

- Profile synthesis function.

- AI function (automatic element judgement).

- Edge detection measurement.

Key features

Auto Element Judgment (AI Function)

The 1600D automatically determines the type of element (point line circle).

Dimension Display Function

The actual measured values for parameters and geometric deviation can be displayed on the diagram.

Profile Synthesis Function (merging of several different profiles)

The limitations on the analysis range due to the angle of the stylus are addressed with the synthesis function.

Peak and Valley Function

This function enables the maximum workpiece point to be detected by tracing with the stylus, simplifying alignment.

Calculation Point Repeat Function

Overall workpiece analysis can be executed after completing only one pattern analysis for workpieces where certain shapes are repeated.

Workpiece Trace Function

The measuring range can be determined by tracing the workpiece once. This is effective for measurement of minute profiles.

Easy Evaluation of Part Contour

Exact data on parts that were previously evaluated with a projector or tool microscope can be obtained in a short period of time. The measured results can be used as is for inspection reports.

High Efficiency Measurement

The teaching/playback function automates the entire process, from measurement to pasting of the data into an inspection report.

Application Areas

- Automotive

- Medical

- Aerospace

- Wind Mill industry