Weld Penetration Defects And Streamlining Of Measurement And Inspection

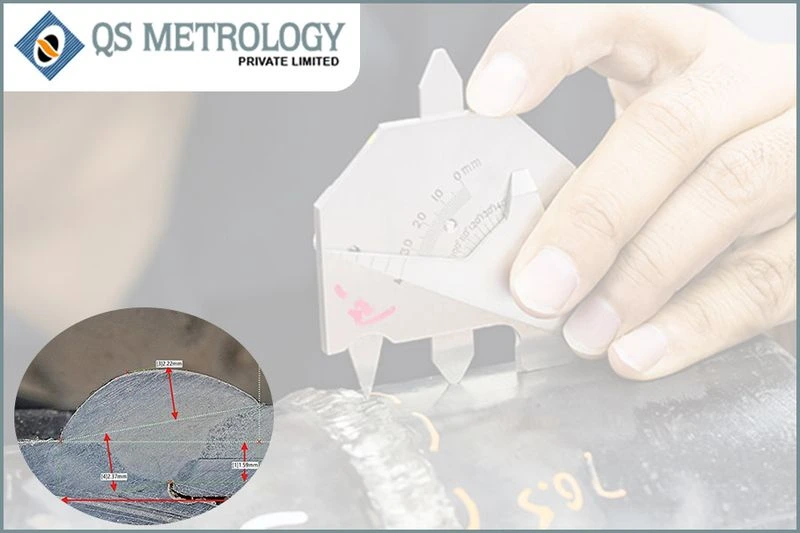

Weld penetration defects and streamlining of measurement and inspectionIf you are into metal joining business, you know the importance of welding. This feature is widely seen used in making items like airplanes, automobiles and so much more! The weld quality can always get assessed by measuring the present dimensions of weld penetration on the current cross-section sample. It helps in inspecting defects like joining failure and insufficient penetration down the road. We, at QS Metrology Private Limited, would like you to know more about the field of Weld penetration inspection and how it has changed the course of time. We will be using the power of 4K digital Microscope, which expresses the boundaries, revolving around metal structure and the defective areas for low-contrast weld cross sections. At the same time, our microscope is able to measure 2D and 3D dimensions at a rather quicker rate and generate measurement results like images and values automatically within a report format. It helps in improving the efficiency level in a rather dramatic manner. Why is weld penetration inspection so vital?From what we have seen so far, welding is widely used to join metallic components for products like ships, railroad cars, planes and automobiles. In terms of automobiles, the joining takes place by using different forms of resistance spot welding, arc welding and laser welding.These techniques are then utilized on frames, bodies, transmissions, engines, chassis and other components, where stress gets applied while driving the automobile.Now you know the importance of strength design of the welds and focusing on the weld quality inspection.For that, we would like to address the dimensional measurement of the cross sections over here.We would like you to know more about Weld penetration analysis in order to get the right measurements done when the time comes. Join hands with our experts as we explore all the features coming along your way over here. Dealing with mechanical properties along with the weld fractures:The welds, which are a perfect combination of weld beads and penetration, help in joining the base materials. They are also the metallic materials like filler materials, which are going to be melted and then solidified. In any field of typical arc welding, the metal structures are subject to change continuously not just in weld metal but in parts of base materials as affected by welding heat.In subject to the change in question, the metal materials’ mechanical properties will also get to change from time to time.Then you have the reinforcement, on the other hand, which will be formed on weld bead surface, which will have discontinuities of own.Such discontinuity concentration will move forward towards mechanical property deviation. It will cause the fractures because of stress concentration.We would like you to know more about Weld penetration measurement before you can plan to deal with mechanical properties of the weld. Our team of mechanics is more than happy to offer the best and most rewarding help, as and when asked for. Focusing on the welding quality:Our team of experts is more than happy to offer the much needed Weld quality inspection if you don’t want to get into trouble later. More than that, we are able to focus on welding quality from start to finish, because we don’t want you to compromise on the results. When it is about the strength design of the metallic items, materials are selected based on the load applied to the final item.The load will get determined first that will be applied to every metallic material out there.On the other hand, the loads on welds of every material must be focused at while determining the strength design.It helps in setting a proper standard for the welding quality that you are planning to achieve right now.It is always important for you to inspect the welding quality, depending on the strength design by measuring the throat thickness, depth of the penetration and the leg length.We will help you to focus on the Weld quality check by dealing with macroscopic measurement of all the cross sections, once you are done with the welding.To help you learn more about the welding quality check and also to gain some information on welding quality related to penetration, we would like you to visit us at QS Metrology Private Limited. Reach out to us by calling at 080 3730 1335 and we will answer it right away!