In modern manufacturing, welding quality is no longer judged by appearance alone. Industries that demand precision, safety, and compliance rely heavily on metrology-driven weld inspection systems to measure and validate welding penetration. From automotive and aerospace to heavy engineering and pressure vessels, accurate measurement of weld penetration has become a critical part of industrial metrology.

Metrology ensures that welding penetration is not just achieved—but measured, verified, documented, and repeatable. This shift from subjective inspection to data-driven measurement highlights why weld inspection systems play a vital role in today’s quality-controlled manufacturing environments.

Understanding Welding Penetration from a Metrology Perspective

Welding penetration refers to the depth to which molten weld metal enters and fuses with the base material. While traditional welding focuses on achieving penetration, metrology focuses on measuring weld penetration accurately and consistently.

In metrology, weld penetration is treated as a measurable parameter, similar to dimensional tolerances or surface roughness. The goal is not only to confirm that penetration exists, but to ensure it falls within specified limits defined by engineering drawings, welding procedures, and international standards.

Why Measuring Weld Penetration Is Critical in Metrology?

Improper or unverified weld penetration can compromise structural integrity, leading to fatigue failure, cracking, or catastrophic breakdowns. In precision manufacturing, assumptions are unacceptable—everything must be measured.

Metrology-based weld inspection ensures –

- Accurate penetration depth measurement

- Repeatability across batches and production lines

- Traceability of weld quality data

- Compliance with ISO, ASME, AWS, and ASTM standards

- Reduced rejection and rework rates

Without reliable measurement, welding penetration remains an estimation rather than a controlled quality parameter.

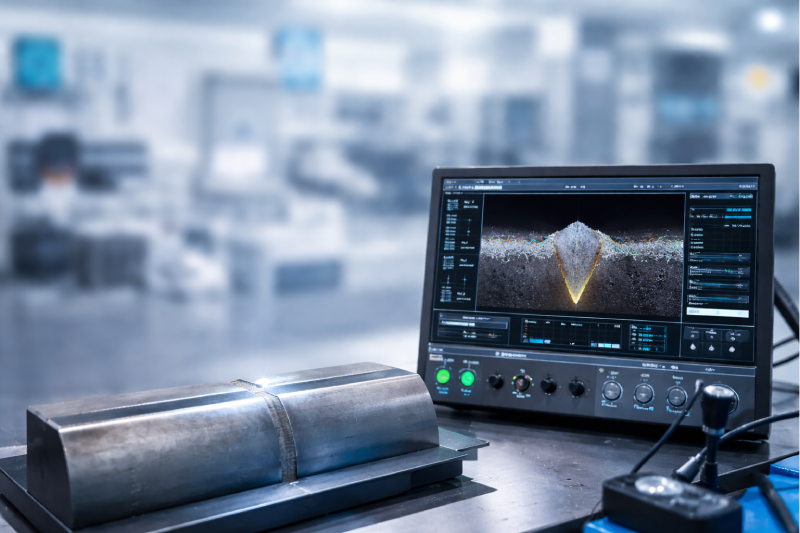

Role of Weld Inspection Systems in Industrial Metrology

A weld inspection system in metrology is designed not only to detect defects, but to quantify weld penetration with measurable accuracy. These systems transform weld inspection from visual judgment into objective data analysis.

Metrology-focused weld inspection systems provide –

- Quantified penetration depth values

- Measurement accuracy and resolution

- Calibration traceability

- Digital documentation for audits and quality control

Such systems are essential in industries where tolerances are tight and safety margins are minimal.

Metrology Techniques for Measuring Welding Penetration

Ultrasonic Measurement Systems

Ultrasonic weld inspection is one of the most widely used metrology techniques for measuring weld penetration depth. Calibrated ultrasonic probes send sound waves through the weld and analyze reflections to determine penetration accuracy.

From a metrology standpoint, ultrasonic systems offer –

- High measurement precision

- Repeatable penetration readings

- Digital data output for analysis

Radiographic Measurement (RT)

Radiographic weld inspection allows internal visualization of weld penetration. In metrology applications, radiographic data is analyzed using measurement software to assess penetration depth and uniformity.

This method is commonly used in pressure vessels, pipelines, and aerospace components.

Laser & Optical Measurement Systems

Advanced metrology uses laser scanners and optical vision systems to evaluate weld geometry and penetration-related parameters. These systems provide non-contact measurement and are ideal for automated production environments.

In-Process Weld Monitoring Systems

Real-time weld inspection systems equipped with sensors and cameras measure welding penetration during the welding process itself. These systems allow immediate correction, ensuring penetration stays within defined limits.

Calibration and Accuracy in Weld Inspection Metrology

In metrology, measurement is meaningless without calibration. Weld inspection systems must be regularly calibrated to ensure accuracy, repeatability, and traceability.

Calibration ensures –

- Penetration measurements are consistent over time

- Inspection systems meet international standards

- Measurement uncertainty is controlled

- Inspection data is reliable for audits and certification

Metrology-driven weld inspection systems follow strict calibration protocols to maintain measurement integrity.

Link Between Welding Penetration Measurement and Structural Integrity

From a metrology viewpoint, weld penetration directly influences mechanical performance. Insufficient penetration results in reduced load-bearing capacity, while excessive penetration may introduce residual stress or distortion.

By precisely measuring welding penetration, manufacturers can –

- Validate weld strength assumptions

- Reduce fatigue-related failures

- Ensure compliance with design tolerances

- Improve long-term product reliability

This data-driven approach separates modern metrology-based welding from traditional methods.

Why Metrology-Based Weld Inspection Is the Future?

As manufacturing shifts toward automation and Industry 4.0, weld inspection systems integrated with metrology software are becoming standard. These systems enable –

- Automated penetration measurement

- Statistical process control (SPC)

- Digital quality records

- Continuous process optimization

In robotic welding lines, metrology ensures that welding penetration remains consistent without relying on operator judgment.

Best Practices for Metrology-Focused Welding Penetration Control

To achieve reliable welding penetration measurement –

- Use calibrated weld inspection systems

- Define penetration tolerances clearly in drawings

- Integrate inspection data with quality management systems

- Perform periodic measurement validation

- Use digital reporting for traceability

These practices align welding processes with modern metrology standards.

In today’s precision-driven industries, welding penetration is no longer just a welding parameter—it is a measurable quality characteristic. Metrology-based weld inspection systems ensure that weld penetration is accurately measured, consistently controlled, and fully traceable.

By adopting advanced metrology techniques for weld inspection, manufacturers can enhance quality, ensure compliance, and build safer, stronger, and more reliable welded products. In the evolving landscape of industrial metrology, accurate measurement of welding penetration is not an option—it is a necessity.