SURFCOM TOUCH 50 - Table top Surface Roughness Tester

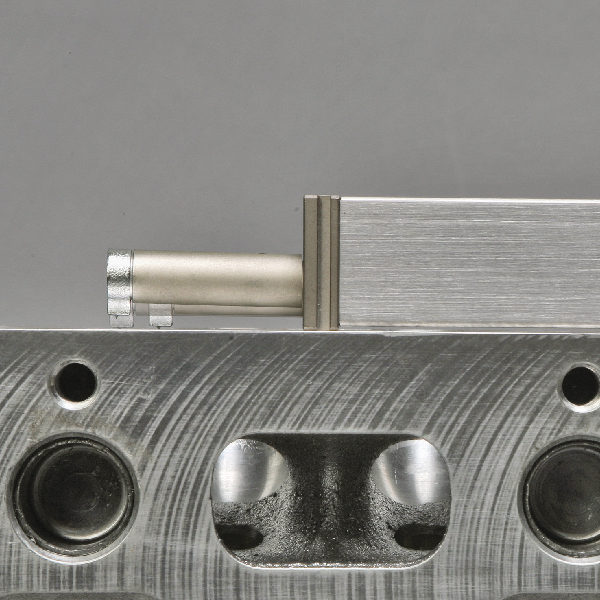

The ZEISS SURFCOM TOUCH 50 is a portable surface roughness and waviness measuring instrument designed for both production environments and dedicated measuring rooms.

SURFCOM TOUCH 50 - Table top Surface Roughness Tester

The ZEISS SURFCOM TOUCH 50 is a portable surface roughness and waviness measuring instrument designed for both production environments and dedicated measuring rooms. It is a compact and high-precision instrument that replaces the older Zeiss SURFCOM 130 and SURFCOM FLEX 50 models.

SURFCOM TOUCH 50 has skid less measurement with a high-performance pickup while having high resolution and with a wide measuring range. Various types of workpieces can be measured by changing the stylus for deep, long, or small holes or a round surface.

Key Features of SURFCOM TOUCH 50 - Table top Surface Roughness Tester

Wide Z-Axis Measurement Range

High Resolution & Accuracy

Intuitive Touchscreen Interface

Skid & Skidless Measurement Modes

Versatile Stylus Options

Find Metrology Solutions In Strategic Industrial Locations

- Surface Roughness and Waviness Measurement: It accurately measures the surface texture of various workpieces, including flat, undulating, stepped, and round surfaces.

- Skidless and Skid Measurement: Offers the flexibility of both skidless (for high accuracy and resolution) and skid (optional) measurement methods.

- High Resolution: Features a high-performance pickup with an extended Z-axis measurement range (800 to 1000 μm) and a minimum resolution of 0.0001 μm, enabling the measurement of intricate details.

- High Straightness Accuracy: Boasts a best-in-class straightness accuracy of 0.3 μm / 50 mm

- Intuitive Touch Panel: Features a large 7-inch color LCD touch panel for easy setup, calibration, measurement, and analysis.

- New Interface: Offers a redesigned interface that enhances operability and reduces the need for instructions.

- Multi-language Support: Provides multi-language support for a global user base

- Wide Range of Styli: Supports a wide variety of interchangeable styli, enabling measurements of deep holes, long holes, small holes, and round surfaces.

- Multiple Standards Support: Complies with various international and national standards, including JIS-2001, JIS-1994, JIS-1982, ISO-1997, ISO-2009, DIN-1990, ASME-1995/2002/2009, and CNOMO.

- Connectivity Options: Features USB and micro USB ports for easy data output to memory devices or printers.

- Portable and Compact: Designed for portability and ease of use in diverse settings.

ZEISS SURFCOM TOUCH 50 is a sophisticated yet user-friendly instrument designed to meet various surface measurement needs with high precision and flexibility.

| Z direction | ±500 μm |

| X direction | 50 mm |

| Evaluation Length | 0.1 to 50 mm |

| Straightness accuracy | 0.3 μm/50 mm |

| Detector vertical movement volume | 50 mm |

| Measurement Speed | 0.15, 0.3, 0.6, 1.5, 3 / 0.05, 0.1, 0.2, 0.5, 1 mm/s (Switching) |

| Pickup Sensing type | Differential inductance |

| Measurement Method | Skid less/Skid (optional) |

| Z direction resolution | 0.0001 μm/±40 μm, 0.00125 μm/±500 μm |

| Measurement force | 0.75 mN |

| Stylus Radius | rtip = 2 μm |

| Stylus Angle | 60°cone |

| Stylus Material | Diamond |

| Calculation Standards | Comply with JIS2013/2001, JIS1994, JIS1982, ISO1997/2009, ISO13565, DIN1990, ASME2002/2009, ASME1995, CNOMO |

| Parameter – Profile Curve | Pa, Pq, Pp, Pv, Pc, PSm, PΔq, PPc, Psk, Pku, Pt, Pmr(c), Pmr, Pδc, Rz82, TILTA, AVH, Hmax, Hmin, AREA, Rmax, Rz, Sm, Δa, Δq, λa, λq, Lr, Rsk, Rku, Rk, Rpk, Rvk, Mr1, Mr2, Vo, K, tp, tp2, Hp |

| Parameter – Roughness Curve | Ra, Rq, Rz, Rv, Rc, Rt, RSm, RΔq, Rsk, Rku, Rmr(c), Rmr, Rδc, Rz94, R3z, RΔa, Rλa, Rλq, Ry, Lr, Sm, S, tp, tp2, PC, RPc JIS, RPc ISO, RPc EN, Pc, PPI, Rp, Rmax, Rz.I, RS, Rmr2, Mr1, Mr2, Rpk, Rvk, Rk, Vo, K, A1, A2, Rpm, Δa, Δq, Htp |

| Parameter – Waviness Profile Curve | Wa, Wq, Wt, Wp, Wv, WSm, WPc, Wsk, Wmr(c), Wmr, Wδc, Wz, Wc, Wku, WΔq, WEM, WEA, WE-a, WE-q, WE-p, WE-v, WE-Sm, WEC-q, WEC-m, WEC-p, WEC-v, WEC-Sm |

| Parameter – Motif | R, Rx, AR, W, Wx, AW, Rke, Rpke, Rvke, NCRX, NR, CPM, SR, SAR, Wte, NW, SAW, SW, Mr1e, Mr2e, Vo, K |

| Evaluation Curve | Profile Curve, Roughness Curve, Filtered Waviness Curve, Waviness Profile Curve, ISO13565 Special Roughness Curve, Roughness motif curve, Waviness motif curve, Upper envelope waviness curve, Rolling Circle Waviness Curve |

| Characteristics graph | Abbot curve, Amplitude density function, Power graph |

| Filter type | Gaussian, 2RC (phase compensation), 2RC (non-phase compensation) |

| Cutoff value – λc | 0.08, 0.25, 0.8, 2.5, 8, 25 mm |

| Cutoff value – λs | None, 2.5, 8, 25 μm |

| Display | 7-inch color liquid crystal touch panel |

| Data output | USB connectors for USB memory, Micro USB connector for USB communication |

| Print output | Inbuilt Thermal printer |

| Language | Japanese, English, Chinese (Traditional Chinese/Simplified Chinese), Korean, Thai, Malay, Vietnamese, Indonesian, German, French, Italian, Czech, Polish, Hungarian, Turkish, Swedish, Dutch, Spanish, Portuguese |

| Power Supply | AC100 to 240 V ±10%, 50/60 Hz, Single phase |

| Power Supply – Charging | Built-in battery (to be charged using AC adaptor), charging period: 3 hours (about 600 measurements can be take when fully charged) |

| Power consumption | Maximum 80 VA |

| External dimensions | Amplification indicator : 320 x 167 x 44 mm/about 4.2 kg for the entire system |

| Standard accessories | Roughness specimen (E-MC-S24C), touch pen (E-MA-S112A), printing paper (E-CH-S25A)*1, instruction manuals, SupportWare II |

How SURFCOM TOUCH 50 - Table top Surface Roughness Tester Work?

The Surfcom Touch 50 tabletop surface roughness tester works by using a precision stylus and high-performance pickup to trace the surface profile of a workpiece and measure its texture with high resolution and accuracy. A stylus with a diamond tip moves across the surface under controlled force and constant speed, detecting microscopic peaks and valleys. As the stylus moves, its vertical deflections are captured by a sensitive sensor and converted into electrical signals. The machine’s electronics and software then analyze these signals to calculate surface roughness and waviness parameters according to international standards, and display the results on an intuitive touchscreen interface. This process allows both skidless and skid measurement methods for different surface types and ensures precise characterization of surface texture across flat, curved, or stepped features.

Locations We Serve

QS Metrology provides SURFCOM TOUCH 50 – Table top Surface Roughness Tester across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Authorized Supplier & Trusted Partner

Expert Product Consultation

Installation & On-Site Demonstration

Calibration, Training & Technical Support

After-Sales Service Across India

FAQs

It is used to measure surface roughness and texture of machined parts with high precision in quality control and inspection workflows.

It uses a precision stylus with a diamond tip that traces the surface profile, detecting microscopic peaks and valleys and converting them into roughness parameters.

It calculates common surface parameters such as Ra, Rz, Rq, Rt, and others in accordance with international standards (ISO, JIS, ANSI).

The tester can measure flat, curved, and stepped surfaces, as well as features like grooves and slots depending on stylus choice and fixturing.

Yes — it supports both skid and skidless measurement modes for greater flexibility across surface types.

Yes — results can be stored internally, exported via USB, and printed or transferred to a PC for reporting and analysis.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.