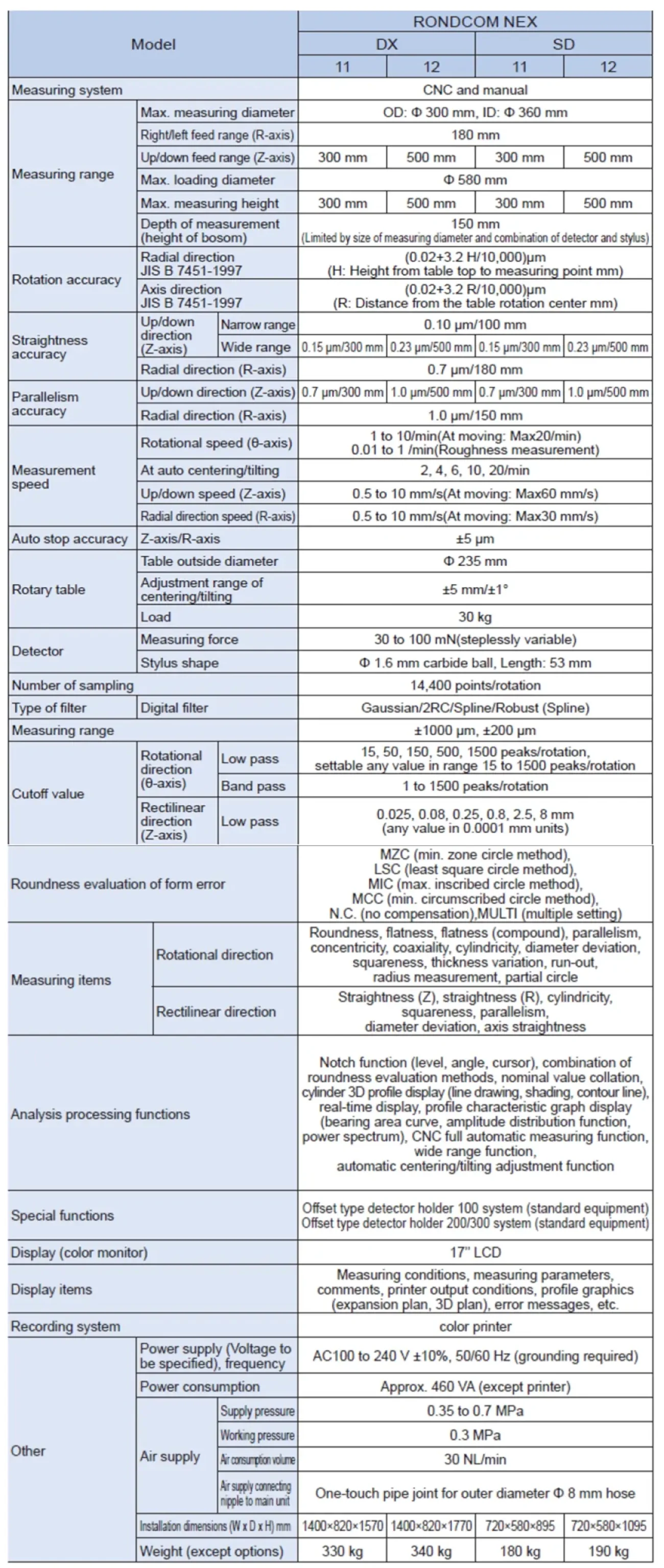

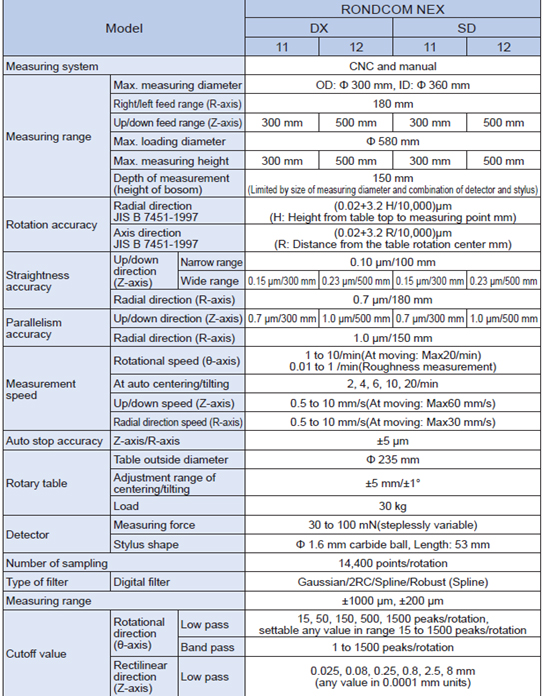

Rondcom NEX DX/SD

Rondcom NEX is a top class high accuracy roundness cylindrical profile measuring instrument.

Rondcom NEX DX/SD

Rondcom NEX is a top class high accuracy roundness cylindrical profile measuring instrument. It is equipped with full new function and meets a need of machined parts high accuracy measurement.

Rondcom NEX has Opposed diameter measuring function to measure inner/ outer diameter

with high repeatability. Can measure a work piece at angles of 0 and 180 degrees. The system can measure the straightness of tapered surface.

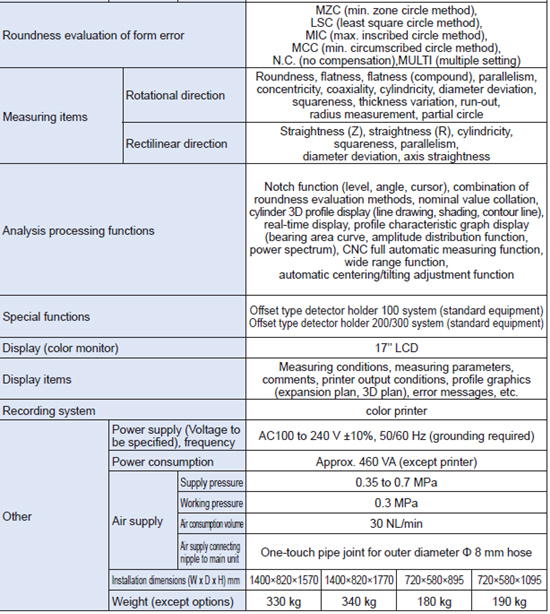

Key Features of Rondcom NEX DX/SD

High‑Precision Roundness & Form Measurement

Advanced Sensor & Probe Technology

Magnetic Linear Drive for Smooth Motion

CNC Automation & Multi‑Point Measurement

Standards‑Compliant Evaluation

How Rondcom NEX DX/SD Work?

The Rondcom NEX DX/SD works by using a high-precision stylus or probe to trace the surface of a rotating part, detecting minute deviations from perfect roundness or form. As the part rotates or the probe moves, radial or vertical displacements are captured by high-resolution sensors and converted into electrical signals. The system’s magnetic linear drive ensures smooth, vibration-free motion, while CNC automation enables fully automated multi-point measurements. The onboard software analyzes the data to calculate roundness, cylindricity, concentricity, and form deviations according to international standards (ISO, JIS, ANSI) and displays graphical profiles and detailed reports for quality control and precision inspection.

Locations We Serve

QS Metrology provides Rondcom NEX DX/SD across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Authorized Supplier & Trusted Partner

Expert Consultation & System Selection

Installation, Calibration & On-Site Support

Operator Training & Technical Assistance

Pan-India After-Sales Service

FAQs

It is used for high‑precision measurement of roundness, cylindricity, and geometric form deviations in precision components.

It uses a high‑resolution stylus or probe to trace the surface while the part rotates or the stage moves, capturing deviations that are analyzed into roundness and form data.

It can measure roundness, cylindricity, concentricity, flatness, and other form characteristics according to international standards.

Yes — with CNC automation, it can perform multi‑point and repeatable measurements with minimal operator intervention.

The instrument uses a magnetic linear drive for smooth, vibration‑free motion, improving accuracy and repeatability.

It is widely used in automotive, aerospace, precision engineering, tool & die, and quality control laboratories for critical form inspection.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.