Basic X-ray Fluorescence Analysis

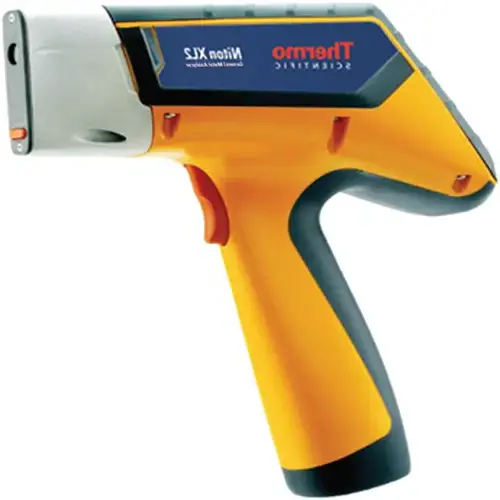

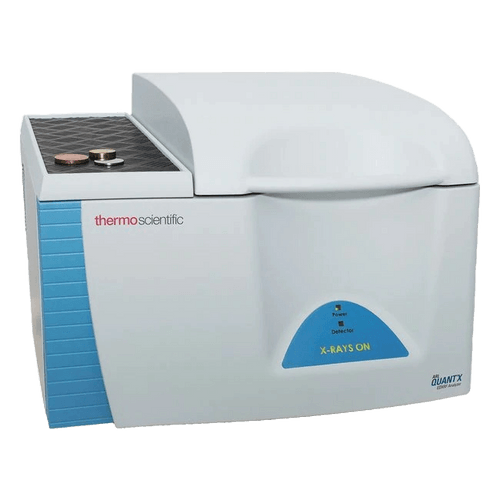

When space and resources are limited or you are trying X-ray analysis for the first time, Thermo Scientific energy-dispersive and compact wavelength-dispersive X-ray fluorescence models offer the easiest route into the exciting world of rapid non-destructive elemental analysis

Key Features of Basic X-ray Fluorescence Analysis

Non-Destructive Elemental Testing

Rapid and Accurate Results

Minimal Sample Preparation

User-Friendly Operation

Cost-Effective Analysis Solution

How Basic X-ray Fluorescence Analysis Work?

Basic X-ray Fluorescence (XRF) analysis works by directing primary X-rays onto a sample, which excites the atoms present in the material. These excited atoms emit secondary (fluorescent) X-rays with energy levels unique to each element. The detector captures these characteristic signals, and the system’s software identifies and quantifies the elements based on their energy and intensity, providing fast, accurate, and non-destructive elemental composition results.

Locations We Serve

QS Metrology provides Basic X-ray Fluorescence Analysis across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Advanced and accurate elemental analysis solutions

Fast, non-destructive testing

Wide range of XRF, XRD, and OES systems

Expert technical and application support

Reliable pan-India service network

FAQs

It is a non-destructive analytical technique used to identify and measure the elemental composition of a material.

Basic XRF can analyze metals, alloys, minerals, powders, and many solid industrial materials.

Minimal to no sample preparation is required, making XRF fast and convenient for routine testing.

Yes, XRF testing does not damage the sample, allowing it to be reused or further analyzed.

It is widely used in manufacturing, automotive, metal processing, mining, and quality control laboratories.

Yes, portable and handheld XRF analyzers enable quick on-site and field-based elemental analysis.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.