In India’s rapidly growing manufacturing sector—whether in automotive hubs like Pune and Chennai, aerospace clusters in Bengaluru, or precision engineering units in Gujarat—quality is everything. One critical yet often underestimated factor that directly impacts product performance is surface roughness.

Many manufacturers focus heavily on dimensions, tolerances, and material grade. However, surface roughness plays an equally vital role in determining how a machined component performs in real-world applications. From friction control to corrosion resistance, surface roughness influences durability, efficiency, and long-term reliability.

This technical breakdown will help Indian businesses clearly understand why surface roughness matters in CNC machining and how controlling it can improve productivity, product life, and profitability.

What Is Surface Roughness?

Surface roughness refers to the microscopic peaks and valleys left on a material surface after machining. Even if a component looks smooth to the naked eye, under magnification, it reveals irregularities created during cutting, grinding, turning, or milling processes.

In CNC machining, surface roughness is affected by –

- Tool geometry

- Cutting speed

- Feed rate

- Depth of cut

- Tool wear

- Machine vibration

- Material properties

Understanding surface roughness is essential because it directly impacts how two surfaces interact when assembled.

Surface Roughness vs Surface Finish

Many Indian manufacturers use the terms interchangeably, but technically they are different.

- Surface finish is a broader term that includes roughness, waviness, and lay.

- Surface roughness specifically measures small-scale irregularities on a surface.

In CNC machining, controlling surface roughness ensures consistency and compliance with international quality standards such as ISO and BIS.

Why Surface Roughness Matters in Indian Industries?

India’s industrial ecosystem includes automotive, railways, defence, heavy engineering, medical devices, and electronics. In each of these sectors, surface roughness plays a critical functional role.

1. Friction and Wear Control

Improper surface roughness increases friction between mating parts. For example –

- Engine components

- Shafts and bearings

- Gear assemblies

High surface roughness accelerates wear, reduces efficiency, and shortens component life. On the other hand, extremely low surface roughness may reduce lubrication retention.

The right level of surface roughness ensures optimal friction balance.

2. Fatigue Strength and Durability

In automotive and aerospace manufacturing, fatigue failure is a serious risk. Excessive surface roughness creates stress concentration points. These microscopic valleys can initiate cracks under cyclic loads.

Indian manufacturers supplying to OEMs must maintain controlled surface roughness to meet fatigue resistance standards.

3. Corrosion Resistance

India’s humid and coastal climate makes corrosion a major issue. Rougher surfaces trap moisture, chemicals, and contaminants. Higher surface roughness increases the exposed surface area, accelerating corrosion.

Reducing surface roughness improves corrosion resistance, especially in industries like –

- Oil & gas

- Marine components

- Chemical processing

4. Sealing Performance

Hydraulic and pneumatic systems widely used in Indian manufacturing rely heavily on controlled surface roughness. If the surface roughness is too high, seals may leak. If it is too low, lubrication may not retain properly.

Maintaining precise surface roughness ensures proper sealing and operational safety.

5. Assembly Fit and Precision

High-precision industries in India, such as defence manufacturing and electronics, demand tight tolerances. Incorrect surface roughness can –

- Affect interference fits

- Impact alignment

- Reduce dimensional accuracy

Thus, managing surface roughness improves overall assembly quality.

Key Surface Roughness Parameters

When discussing surface roughness, certain measurement parameters are widely used in CNC machining –

Ra (Arithmetic Average Roughness)

The most common parameter. It represents the average deviation from the mean line. Indian industries often specify surface roughness in terms of Ra.

Rz (Average Maximum Height)

Measures the average of peak-to-valley heights within sampling lengths.

Ry (Maximum Roughness Depth)

Represents the largest peak-to-valley height within the evaluation length.

Understanding these surface roughness parameters helps manufacturers meet both domestic and export standards.

How Surface Roughness Is Measured

Accurate measurement of surface roughness ensures process control and quality compliance.

1. Comparative Methods

Using standard comparison samples to visually or tactually match surface roughness levels. Suitable for workshop-level checks.

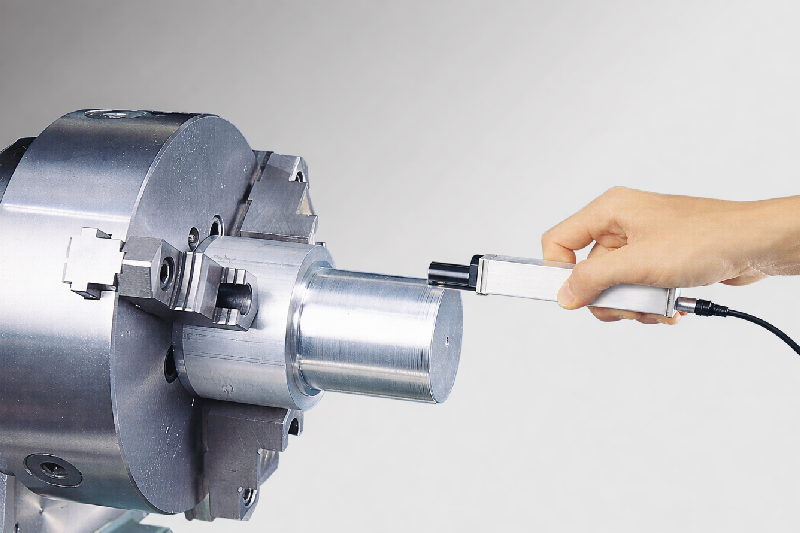

2. Stylus Profilometers

A stylus moves across the surface and records variations. This is the most widely used method for measuring surface roughness in CNC machining.

3. Optical Methods

Advanced non-contact systems use light interference to measure surface roughness. These are ideal for high-precision industries.

For Indian MSMEs upgrading toward Industry 4.0, investing in accurate surface roughness measurement tools can significantly improve quality standards.

Factors Affecting Surface Roughness in CNC Machining

To control surface roughness, manufacturers must manage –

- Proper feed rate optimization

- Tool sharpness and maintenance

- Stable machine setup

- Appropriate cutting parameters

- Coolant application

Poor tooling practices increase surface roughness, which leads to rework and rejection.

Surface Roughness and Cost Efficiency

Many Indian manufacturers focus only on speed to increase output. However, neglecting surface roughness can lead to –

- Higher rejection rates

- Customer complaints

- Reduced export opportunities

- Increased warranty costs

Optimizing surface roughness reduces post-processing, improves consistency, and enhances customer trust.

The Strategic Advantage for Indian Manufacturers

With the “Make in India” initiative and growing global exports, Indian industries must compete internationally. Controlling surface roughness is no longer optional—it is a competitive requirement.

Proper management of surface roughness results in –

- Higher product reliability

- Improved performance

- Better compliance with global standards

- Increased customer satisfaction

In CNC machining, surface roughness is not just a technical specification—it is a performance determinant. For Indian businesses aiming to scale globally, understanding and controlling surface roughness can be the difference between average quality and world-class manufacturing.

Whether you are operating a small machining unit in Coimbatore or a large automotive plant in Gurugram, investing in better control of surface roughness will enhance product quality, durability, and profitability. In today’s competitive industrial landscape, mastering surface roughness is mastering precision itself.