High-Speed ZEISS Contour Measuring Machine

ZEISS Contour Measuring Machine

Looking for a reliable and high-precision contour measuring machine in Uttar Pradesh? We offer advanced contour measuring machine in Uttar Pradesh solutions designed to deliver superior surface and profile inspection, high dimensional accuracy, and dependable industrial measurement performance. Our modern contour measuring systems support manufacturers, quality control laboratories, and engineering facilities across Uttar Pradesh by enabling precise and repeatable measurement results that strictly comply with exact design and tolerance specifications.

Uttar Pradesh is steadily emerging as a major industrial and manufacturing hub, with increasing demand from automotive components, precision engineering, aerospace prototyping, and tool manufacturing industries. To meet stringent quality standards and complex surface and profile measurement requirements, businesses increasingly rely on a high-performance contour measuring machine in Uttar Pradesh to ensure accurate, efficient, and consistent inspection processes.

Key Features of Contour Measuring Instruments

High-Speed Magnetic Drive for Fast, Smooth Measurements

Noise-Free Operation for Accurate, Reliable Readings

High-Resolution Sensors Capture Fine Contours Precisely

Ensures Quality Control Across Industries

Robust, User-Friendly Design for Consistent Measurements

Reliable Contour Measuring Instrument Provider in India

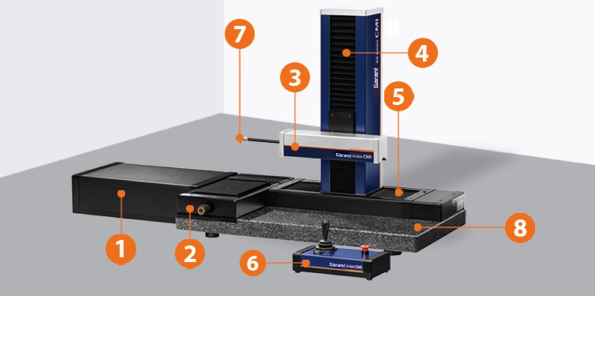

QS Metrology offers high-precision Contour Measuring Instruments engineered for accuracy, stability, and efficient inspection. Our instruments feature granite guideways, pre-loaded air bearings, servo-controlled motion, and intuitive 3D measurement software, ensuring consistent and reliable results. Built to international standards, QS Metrology’s contour measuring instruments deliver precise measurements with excellent performance at competitive prices. Get in touch today to discover the ideal measurement solution for your needs.

Contour Measuring Instruments We Offer

How Contour Measuring Instruments Work

Contour measuring instruments work by precisely tracing the surface profile and geometry of a component to capture its shape and dimensions. Using a highly sensitive probe or stylus, the instrument moves along the contour of the part, recording positional data in multiple axes. Advanced models employ magnetic linear drives and servo-controlled motion for fast, smooth, and accurate scanning. The collected data is processed by specialized 3D measurement software, which generates detailed profiles, identifies deviations, and ensures that the component meets exact dimensional and quality standards. This process is essential for quality control, reverse engineering, and precision manufacturing applications.

Locations We Serve

QS Metrology provides Contour Measuring Instruments across India, serving all major industrial regions, including :

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Trusted Provider

Reliable partner for precision contour measurement.

Advanced Instruments

Solutions for all contour inspection needs.

Expert Support

Skilled assistance and calibration services.

Competitive Pricing

High-quality instruments with dependable after-sales service.

Industry Experience

Serving automotive, aerospace, medical, and electronics sectors.

Customized Solutions

Tailored setups for your specific measurement requirements.

FAQs

A Contour Measuring Instrument is a precision metrology device used to measure the profile, contour, form, and surface geometry of components with high accuracy.

They are used for inspecting profiles, radii, angles, step heights, grooves, and complex shapes to ensure components meet design specifications and quality standards.

Contour measuring instruments are commonly used in automotive, aerospace, medical devices, tooling, electronics, and precision manufacturing industries.

These instruments provide high-resolution and repeatable measurements, offering micron-level accuracy depending on the model, probe system, and measurement conditions.

Yes, they feature intuitive software, automated measurement functions, and user-friendly interfaces, making them suitable for both experienced metrologists and shop-floor operators.

Yes, professional installation, user training, calibration, and reliable after-sales technical support are provided to ensure consistent performance and long-term accuracy.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.