Contourecord 1600G

Flexible CNC measuring station for contour measurements. The instrument is designed to measure any intricate profile in a 2 dimensional format. The measured profile can be post-processed in the advanced ACCTee software to analyze the profile and extract dimensional details.

Key features

Auto Element Judgment (AI Function)

The 1600D automatically determines the type of element (poin tline circle).

Dimension Display Function

The actual measured values for parameters and geometric deviation can be displayed on the diagram.

Profile Synthesis Function (merging of several different profiles)

The limitations on the analysis range due to the angle of the stylus are addressed with the synthesis function.

Peak and Valley Function

This function enables the maximum workpiece point to be detected by tracing with the stylus, simplifying alignment.

Calculation Point Repeat Function

Overall workpiece analysis can be executed after completing only one pattern analysis for workpieces where certain shapes are repeated.

Workpiece Trace Function

The measuring range can be determined by tracing the workpiece once. This is effective for measurement of minute profiles.

Easy Evaluation of Part Contour

Exact data on parts that were previously evaluated with a projector or tool microscope can be obtained in a short period of time. The measured results can be used as is for inspection reports.

High Efficiency Measurement

The teaching/playback function automates the entire process, from measurement to pasting of the data into an inspection report.

ACCTee Contour profile meausurment and analysis

- Work Trace Function

- Stylus Calibration Wizard

- Peak and Valley function

- Calibration alarm

- Master ball calibration function (patented)

- Pitch calculation function

- Profile symthesis function

- AI function (automatic element judgement)

- Edge detection measurement

Find Metrology Solutions In Strategic Industrial Locations

- Automotive

- Medical

- Aerospace

- Wind Mill industry

How Contourecord 1600G Work?

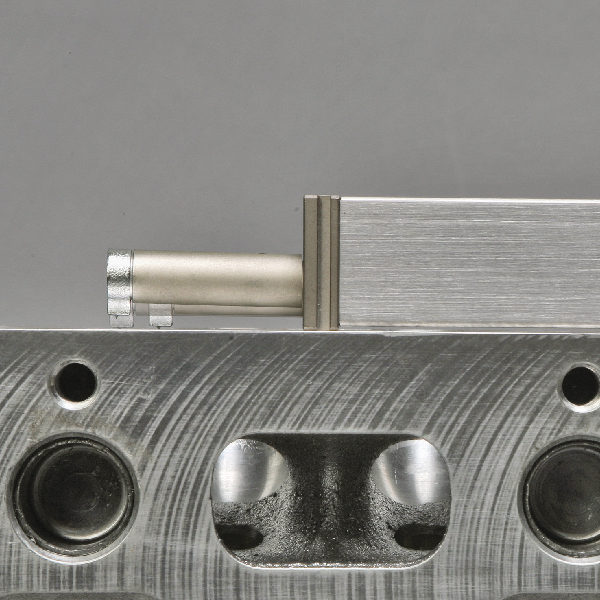

The Contourecord 1600G works by using a precision probe or stylus to trace the surface profile and contours of a workpiece. As the probe moves along the part, microscopic vertical and lateral displacements are detected by high‑resolution sensors. These movements are converted into electrical signals, which the onboard electronics and software analyze to calculate geometric features, contour accuracy, roundness, and form deviations according to international standards. The system’s high-precision linear guides and optional CNC control ensure smooth, repeatable motion, while the software displays measurements, graphs, and evaluation results on a touchscreen interface, allowing fast, accurate, and comprehensive form and contour inspection.

Locations We Serve

QS Metrology provides Contourecord 1600G across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Customized Solutions & Trusted Provider

Advanced Instruments

Expert Support

Competitive Pricing

Industry Experience

FAQs

It is used for precision form and contour measurement, including roundness, profile, and geometric features of machined parts.

It uses a high‑resolution probe or stylus to trace the surface and captures minute deviations, which are processed into form and contour data.

It can measure roundness, cylindricity, profile, waviness, and form deviations on various part geometries.

Yes — it evaluates measurements according to international standards like ISO, JIS, and ANSI for form and contour analysis.

Yes — with its large measuring range and travel, it accommodates a variety of part sizes and shapes.

Many models support automated measurement sequences and CNC control for repeatable, high‑throughput inspection.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.