High-Precision Coordinate Measuring Machine (CMM)

Zeiss has built CMMs for more applications than any other 3d CMM manufacturer-with thousands of 3d CMMs currently in service around the globe. And they are committed to continuing innovation, spending at least ten percent of CMM revenues on research and development every year.

What Is a Coordinate Measuring Machine?

A Coordinate Measuring Machine (CMM) is a precision measuring system used to check the exact size, shape, and geometry of a manufactured part. It works by touching or scanning the surface of a component and recording its position in a three-dimensional space. The main purpose of a CMM is to make sure parts are produced exactly as designed, which is essential for maintaining quality and consistency in manufacturing. By providing highly accurate and repeatable measurements, CMMs help manufacturers detect errors early, reduce rework, and improve overall process efficiency. These machines are commonly used to carry out dimensional measurements such as lengths, diameters, and heights, geometric inspections including flatness, straightness, and concentricity, as well as tolerance checks to confirm that components meet specified design requirements.

Key Features of Coordinate Measuring Machines

High Accuracy, Repeatability & Advanced Probing

Robust Granite Structure & Thermal Stability

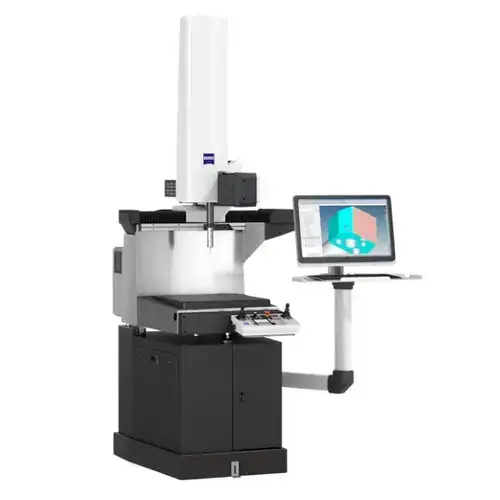

User-Friendly Software with CAD Compatibility

Fast Inspection Performance

Highly precise and stiff air bearings

Find Metrology Solutions In Strategic Industrial Locations

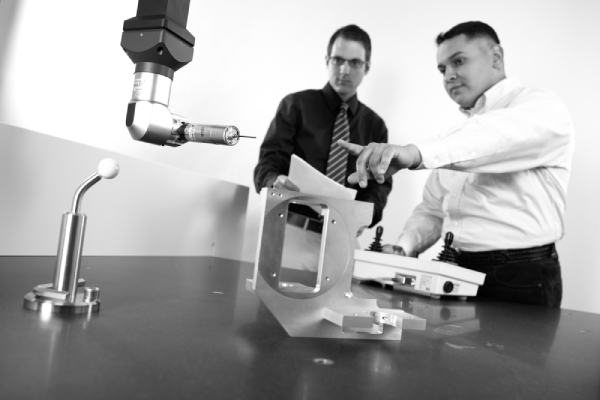

How Coordinate Measuring Machine Work?

A Coordinate Measuring Machine (CMM) works on the principle of coordinate geometry to accurately measure the physical dimensions of a component. The machine uses a precision probe to touch or scan the surface of the part, capturing multiple discrete points as it moves along the X, Y, and Z axes. These data points are used to calculate exact dimensions and geometric features.

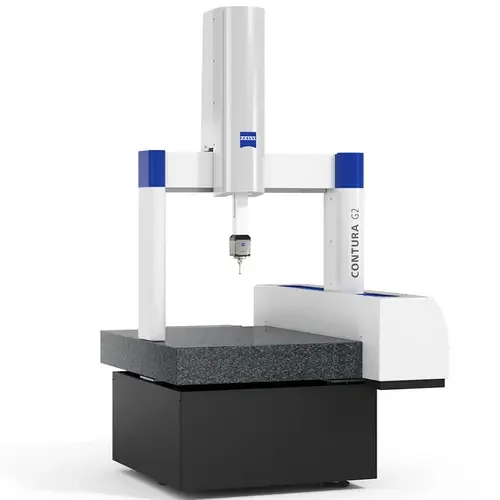

QS Metrology CMMs are built with a high-grade granite table that provides exceptional flatness, rigidity, and long-term stability. Fixtures are used to securely hold components in place, ensuring repeatable and error-free measurements. Optical sensors precisely track probe movement, and the collected data is processed through advanced CMM software to analyze dimensions and generate detailed inspection reports.

Thanks to their accuracy and versatility, QS Metrology CMMs are widely used in industries such as automotive, aerospace, medical devices, and electronics for reliable and precise quality inspection.

Coordinate Measuring Machine Products We Offer

Trusted Coordinate Measuring Machine (CMM) Provider in India

QS Metrology delivers high-precision Coordinate Measuring Machines designed for accuracy, stability, and fast inspection. Our CMMs feature granite guideways, pre-loaded air bearings, servo-controlled motion, and user-friendly 3D measurement software for consistent, reliable results. Built to global standards, QS Metrology CMMs offer accurate measurements at competitive prices. Contact us today to find the right CMM solution for your application.

Locations We Serve

QS Metrology offers CMM solutions across India, covering all major industrial regions, including: Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Trusted Metrology Solutions Provider

Authorized and reliable partner for precision measurement.

Wide Range of Advanced CMM Systems

Machines for all types of inspection and industrial needs.

Expert Support & Calibration Services

Skilled technical assistance to ensure optimal performance.

Competitive Pricing & After-Sales Service

High-quality machines at the right price with dependable support.

Industry Experience Across Sectors

Serving automotive, aerospace, medical, electronics, and more.

Customized Solutions

Tailored CMM setups to meet your specific inspection requirements.

FAQs

A Coordinate Measuring Machine (CMM) is a precision inspection device used to accurately measure the dimensions, shape, and geometry of manufactured components in three axes (X, Y, and Z).

This CMM is ideal for dimensional inspection, quality control, first article inspection (FAI), part verification, and tolerance checking across various manufacturing processes.

The machine is suitable for automotive, aerospace, medical devices, electronics, engineering, and precision manufacturing industries.

The CMM delivers high-precision, repeatable measurements with micron-level accuracy, depending on the model, probe configuration, and operating environment.

Yes, the CMM features user-friendly measurement software, intuitive controls, and automated inspection capabilities, making it suitable for both skilled operators and new users.

Yes, complete installation, operator training, calibration, and after-sales technical support are provided to ensure optimal machine performance and long-term reliability.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.