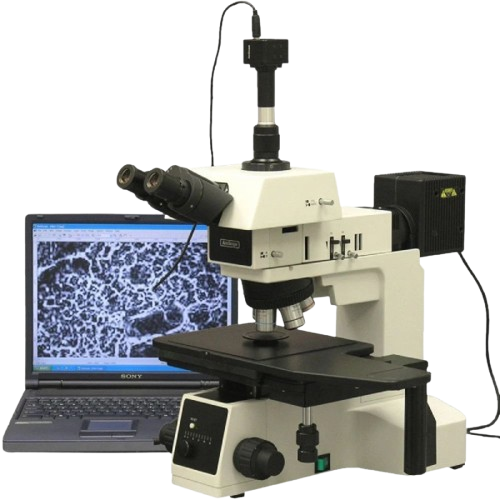

MJ6408 Metallurgical Microscopes

Key Features of MJ6408 Metallurgical Microscopes

Wide Magnification Range (100×–1000×)

Infinity Plan Objectives for Sharp Imaging

Trinocular Head for Camera Integration

Stable Mechanical Stage for Precise Positioning

Reflected LED Illumination for Opaque Samples

| Total Magnification – 100X to 1000X |

| Infinity Plan Objectives – PL 10X, PL 20X, PL 50X, PL 100X – X 10 with Eye piece |

| Eye piece – Wide field 10X/20mm |

| Mechanical stage is 150 X 200 mm with X-Y movements |

| The mechanical stage has low positioned co-axial |

| Equipped with frosted glass and yellow, green and blue filters |

| Integrated field diaphragm, aperture diaphragm and puller type polarizer |

| Inverted quadruple nosepiece revolves on ball bearings, with click-stop mechanism |

| Trinocular Siedentopf head inclined at 45 degree |

| Axial focusing controls with large knobs, PRE-FOCUSSING LEVER and TENSION ADJUSTMENT RING. |

| Controls on balls rolling on guide ways |

| Hand rest on both sides |

| Phototube for photomicrography |

| Diopter adjustment ring on ocular tube |

| Interpupillary distance from 53 mm to 75 mm. |

| Koehler’s illumination system with 6 V / 30 W halogen lamp, adjustable brightness. |

| Power – 220 V, 50 Hz AC |

| Comes in a box, with spare bulbs, operating manual and dust cover |

How MJ6408 Metallurgical Microscopes Work?

The MJ6408 Metallurgical Microscope works by using reflected LED illumination to examine opaque samples such as metals, alloys, and ceramics. Light is directed from above onto the sample surface, and the reflected light passes through high-quality infinity plan objectives to produce sharp, detailed images of microstructures, grain boundaries, and surface defects. The trinocular head allows comfortable viewing and supports camera attachment for documentation or digital analysis. A stable mechanical X-Y stage enables precise sample positioning, while coarse and fine focus controls ensure accurate focusing at various. magnifications, ranging from 100× to 1000× This setup makes the MJ6408 ideal for industrial quality control, material research, and educational applications.

Locations We Serve

QS Metrology provides MJ6408 Metallurgical Microscopes across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

High-Quality, Precision Optics

Advanced Illumination & Contrast Techniques

Durable, Vibration-Free Mechanical Stages

Digital Imaging & Analysis Compatibility

Expert Support & Pan-India Service

FAQs

It provides a wide magnification range from about 100× to 1000×, suitable for detailed metallurgical analysis.

It uses infinity plan objectives (e.g., PL 10×, 20×, 50×, 100×) that deliver sharp and clear imaging for microstructure inspection.

Yes — the trinocular head allows you to attach a camera for documentation, live display, or analysis without affecting viewing.

It uses reflected LED illumination, which lights up opaque metal surfaces from above for high‑contrast observations.

Yes — it includes a stable mechanical stage with smooth X‑Y movement to accurately position the sample under observation.

It is ideal for material inspection, quality control, metallography, and research labs where detailed surface structure analysis of metals and alloys is needed.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.