Rondcom Touch Tester

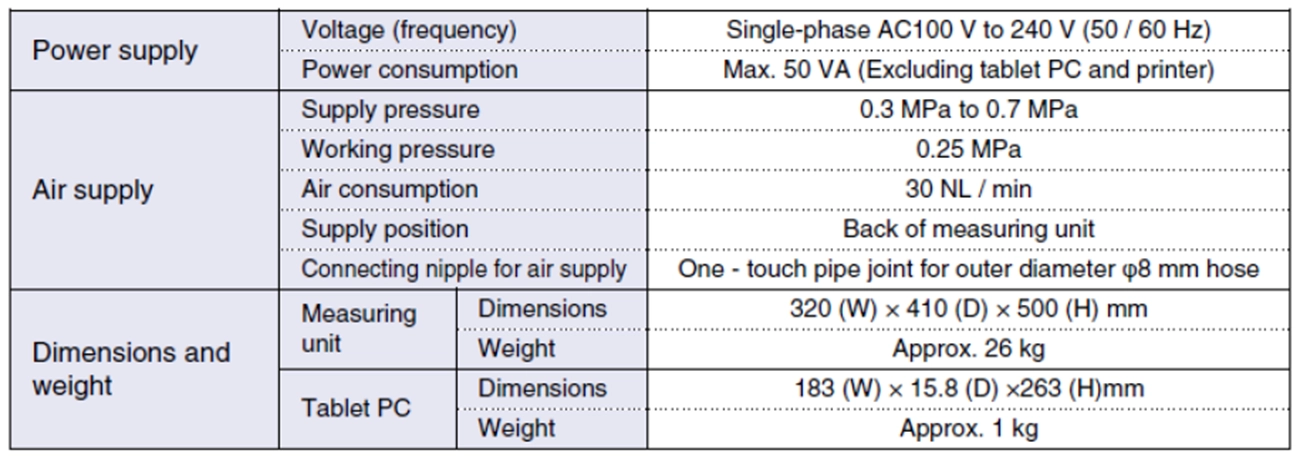

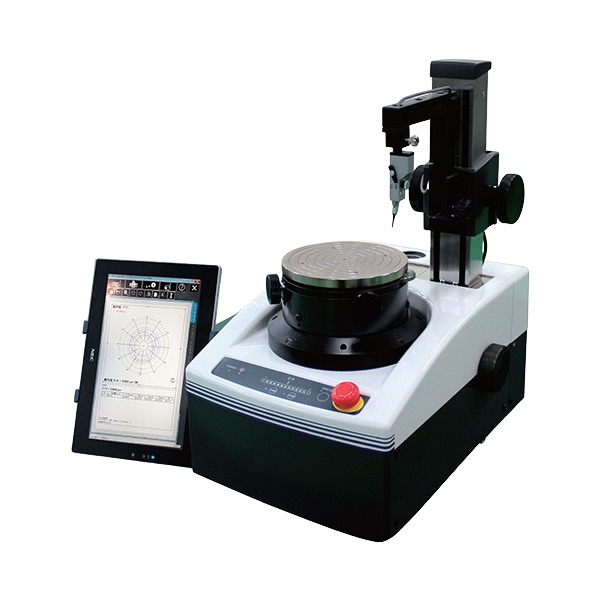

RONDCOM TOUCH is a compact Form Tester for Production. The system is ideal for self-tests directly in production. Thanks to its compact design, the form tester is suitable for any workbench.

Rondcom Touch

RONDCOM TOUCH is a compact Form Tester for Production. The system is ideal for self-tests directly in production. Thanks to its compact design, the form tester is suitable for any workbench.

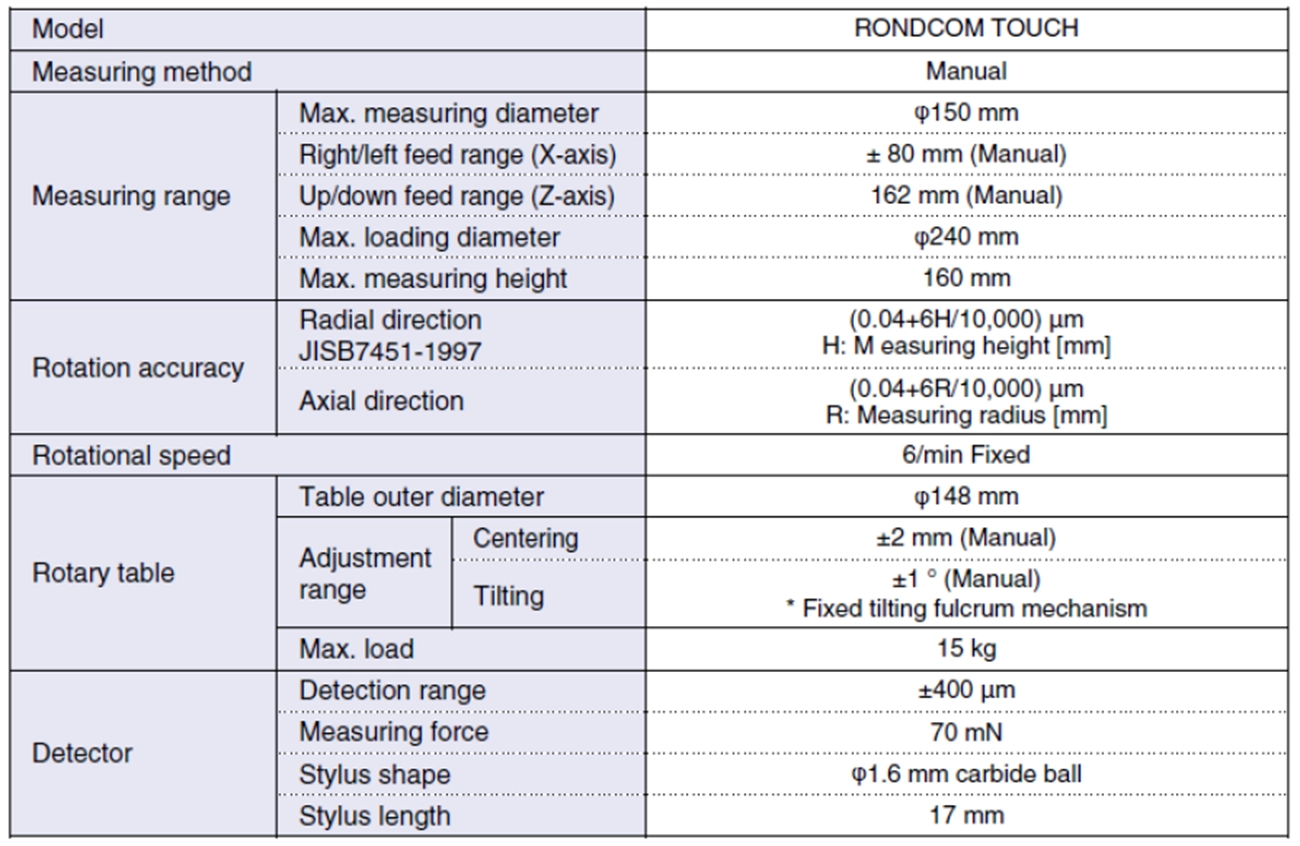

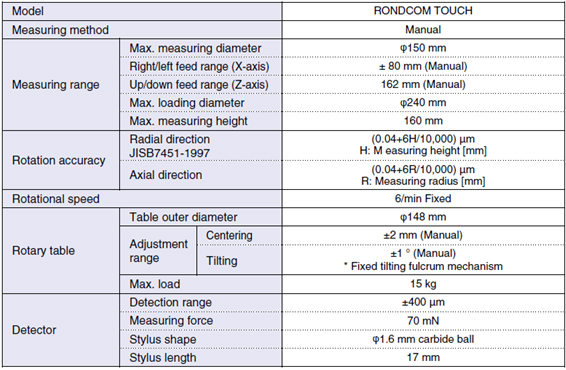

The form tester features a movable X axis, allowing it to reach workpieces from all sides without difficulty. Another key benefit is the rotary table on air bearings that achieves extremely high rotational accuracy thanks to its excellent rigidity. In addition, the non-contact travel ensures measurement results that are totally uninfluenced by drive vibrations.

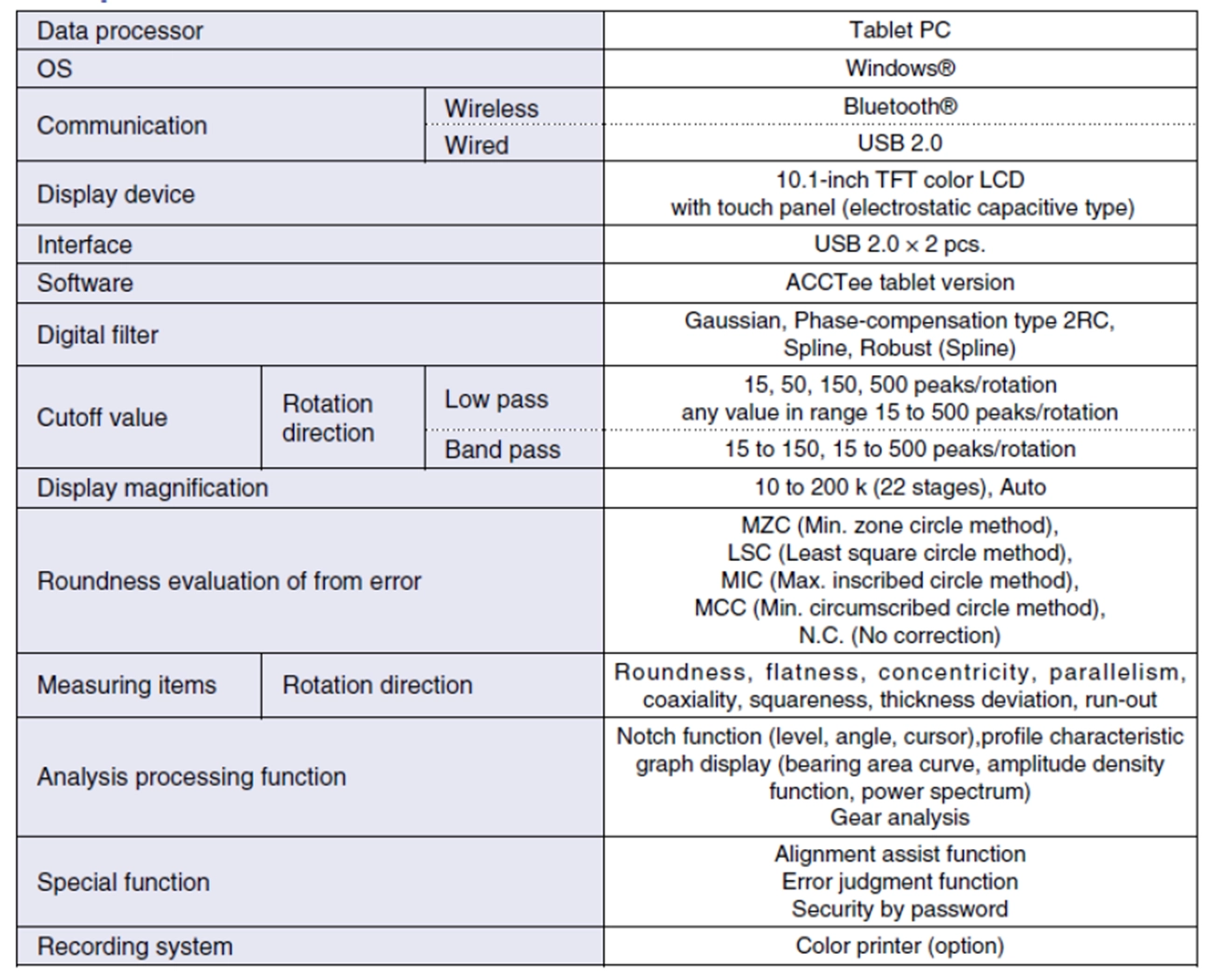

The software ACCTee PRO provides support in the semiautomatic alignment of the part. Just three touches of the touch screen suffice to receive a detailed measuring report. Alternatively, RONDCOM TOUCH can also be operated via a conventional desktop PC.

Key Features of Rondcom Touch Tester

High‑Precision Roundness & Form Measurement

Intuitive Touchscreen Operation

Advanced Probe & Sensor Technology

Standards‑Compliant Evaluation (ISO/JIS/ANSI)

Automated Measurement & Reporting

How Rondcom Touch Tester Work?

The Rondcom Touch Tester works by using a precision stylus or probe to trace the surface of a rotating part, detecting minute deviations from a perfect circle or form. As the part rotates, the stylus measures radial variations along the surface, which are converted into electrical signals. The onboard software then analyzes these signals to calculate roundness, cylindricity, concentricity, and other form parameters according to international standards (ISO, JIS, ANSI). With a touchscreen interface and automated routines, the system allows fast, accurate, and repeatable measurements, producing detailed graphical profiles and reports for quality control and inspection.

Locations We Serve

QS Metrology provides Rondcom Touch Tester across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Authorized Supplier & Trusted Partner

Expert Consultation & System Selection

Installation, Calibration & On-Site Support

Operator Training & Technical Assistance

Pan-India After-Sales Service

FAQs

It is used for precision measurement of roundness, cylindricity, and form accuracy of rotational parts.

A high-resolution stylus or probe traces the part surface while it rotates, detecting deviations that are analyzed by software to calculate roundness and form parameters.

It measures roundness, cylindricity, concentricity, flatness, and geometric form deviations according to international standards.

Yes — it complies with ISO, JIS, ANSI, and ASME for precision roundness and form measurement.

Yes — it supports automated measurement routines and reporting, reducing operator intervention and improving repeatability.

It is widely used in automotive, aerospace, precision engineering, tool & die, and quality control laboratories.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.