Surface Roughness Measuring Instrument

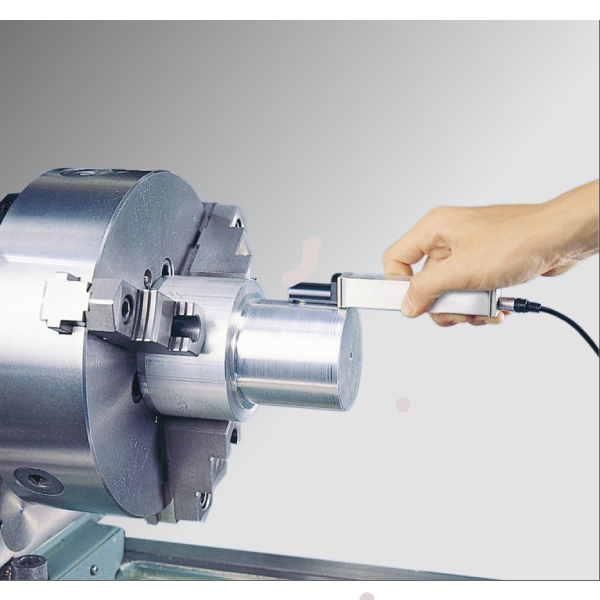

Surface Roughness Testers from Zeiss allows easy measurements of various types of work pieces. These systems comes with an intuitive and easy-to-use screen for condition setting,calibration, measurement and analysis.

What Is Surface Roughness Tester?

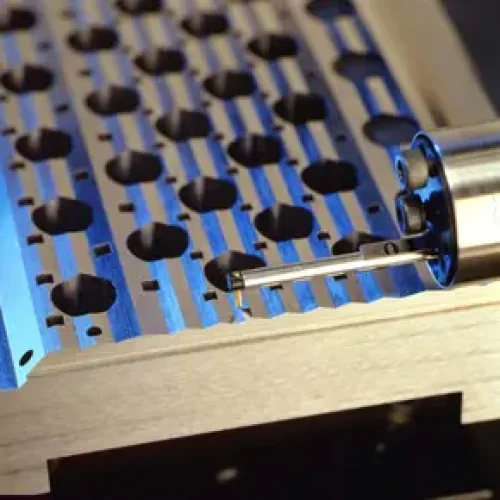

A Surface Roughness Tester is a precision instrument used to measure the surface texture and finish of materials. It evaluates microscopic surface irregularities such as peaks and valleys created during machining. The tester measures parameters like Ra, Rz, Rq, and Rt to assess surface quality. It works using a stylus probe that moves across the surface and records vertical variations. These movements are converted into electrical signals and displayed as numerical values or profiles. Surface roughness testing ensures quality, consistency, and compliance with standards. It is widely used in automotive, aerospace, manufacturing, and quality control applications.

Key Features of Surface Roughness Testers

Accurate measurement of Ra, Rz, Rq, and Rt parameters consistently

High-precision stylus technology for reliability

Easy-to-use digital interface with clarity

Compact and portable design for flexibility

Meets international quality standards globally accepted

Find Metrology Solutions In Strategic Industrial Locations

Trusted Surface Roughness Measuring Instrument in India

QS Metrology offers high-precision Surface Roughness Measuring Instruments designed to deliver accurate, fast, and reliable surface finish evaluation for industrial applications. Our instruments are compact, durable, and easy to operate, featuring advanced stylus technology and intuitive software for precise measurement of surface roughness parameters across a wide range of materials. Engineered to meet international quality standards, QS Metrology’s solutions ensure consistent, repeatable, and reliable results for inspection and quality control.

Surface Roughness Measuring Instruments We Offer

How Surface Roughness Tester Work?

A Surface Roughness Tester works by using a stylus probe that moves smoothly across the surface being measured. As the stylus travels over microscopic peaks and valleys on the surface, its vertical movements are detected and converted into electrical signals. These signals are then processed by the instrument’s internal electronics and software to calculate surface roughness parameters such as Ra, Rz, and Rq. The measured values and surface profile are displayed digitally, allowing accurate evaluation of surface finish for quality control and inspection purposes.

Locations We Serve

QS Metrology provides Surface Roughness Tester across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Trusted and authorized metrology solutions provider

High-precision and reliable surface roughness testers

Instruments compliant with international quality standards

Expert technical support and calibration services

Competitive pricing with dependable after-sales support

FAQs

A Surface Roughness Measuring Instrument is a precision device used to measure surface texture parameters such as Ra, Rz, and other roughness values to evaluate surface quality.

They are used to inspect surface finish, detect machining defects, and ensure components meet required surface standards in manufacturing and quality control processes.

These instruments are widely used in automotive, aerospace, medical devices, tool rooms, electronics, and precision engineering industries.

Common parameters include Ra, Rz, Rt, Rq, and other international surface roughness standards, depending on the instrument model and software capabilities.

Yes, most instruments feature intuitive controls, clear displays, and automated measurement functions, making them suitable for both shop-floor and laboratory use.

Yes, professional calibration, operator training, and reliable after-sales technical support are provided to ensure accurate and consistent measurements.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.