ZEISS Surface Roughness Measuring Instrument

ZEISS Surface Roughness Measuring Instrument

Looking for a reliable surface roughness tester in Jammu & Kashmir? QS Metrology offers premium ZEISS surface roughness measuring instruments in Jammu & Kashmir designed to deliver precise roughness tests, accurate surface finish evaluation, and dependable industrial measurement results. Our ra tester in Jammu & Kashmir solutions help manufacturers, quality control laboratories, and engineering units across Jammu & Kashmir achieve accurate, repeatable, and standard-compliant roughness measurement outcomes.

Jammu & Kashmir is gradually growing as an industrial hub with rising requirements in automotive, aerospace, tooling, and precision engineering sectors. Businesses increasingly depend on a high-performance surface roughness tester in Jammu & Kashmir and advanced surface roughness measuring instruments in Jammu & Kashmir to maintain stringent surface finish standards and ensure reliable inspection processes. ZEISS ra tester in Jammu & Kashmir guarantees superior surface quality, reduced rework, and enhanced product reliability.

Key Features of Surface Roughness Testers

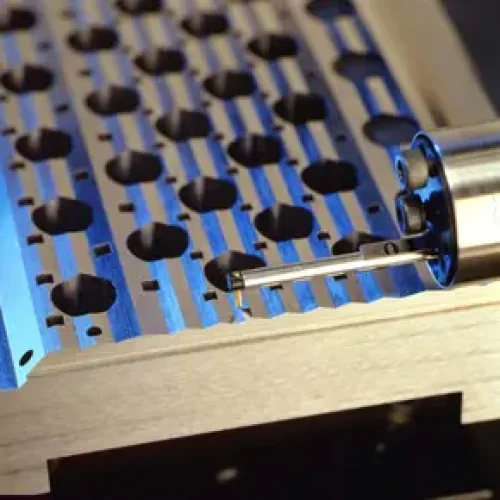

Accurate measurement of Ra, Rz, Rq, and Rt parameters consistently

High-precision stylus technology for reliability

Easy-to-use digital interface with clarity

Compact and portable design for flexibility

Meets international quality standards globally accepted

Surface Roughness Measuring Instruments We Offer

Why Choose QS Metrology?

Trusted and authorized metrology solutions provider

High-precision and reliable surface roughness testers

Instruments compliant with international quality standards

Expert technical support and calibration services

Competitive pricing with dependable after-sales support

FAQs

A Surface Roughness Measuring Instrument is a precision device used to measure surface texture parameters such as Ra, Rz, and other roughness values to evaluate surface quality.

They are used to inspect surface finish, detect machining defects, and ensure components meet required surface standards in manufacturing and quality control processes.

These instruments are widely used in automotive, aerospace, medical devices, tool rooms, electronics, and precision engineering industries.

Common parameters include Ra, Rz, Rt, Rq, and other international surface roughness standards, depending on the instrument model and software capabilities.

Yes, most instruments feature intuitive controls, clear displays, and automated measurement functions, making them suitable for both shop-floor and laboratory use.

Yes, professional calibration, operator training, and reliable after-sales technical support are provided to ensure accurate and consistent measurements.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.