SURFCOM 1400

Advanced Surface Roughness Measurement system with Superior Operability & Automation from Measurements to Inspection Report Creation

SURFCOM 1400

Advanced Surface Roughness Measurement system with Superior Operability & Automation from Measurements to Inspection Report Creation

Key Features of SURFCOM 1400 in India

AI-Assisted Automatic Measurement

Enhanced Automation & Reporting

Advanced Evaluation Functions

Compliance with Global Standards

Expandable & Upgradable System

Find Metrology Solutions In Strategic Industrial Locations

- The unit automatically selects the measuring conditions without setting them in advance (roughness measurement).

- A lesson mode is available to teach the user the operation procedures.

- This model complies with the latest ISO, JIS, DIN, ASME, CNOMO and other standards, and has cleared the requirements for the European safety standard CE marking.

- It supports operation using Japanese, Chinese, Korean English, German, French, Italian and Spanish.

How SURFCOM 1400 Work?

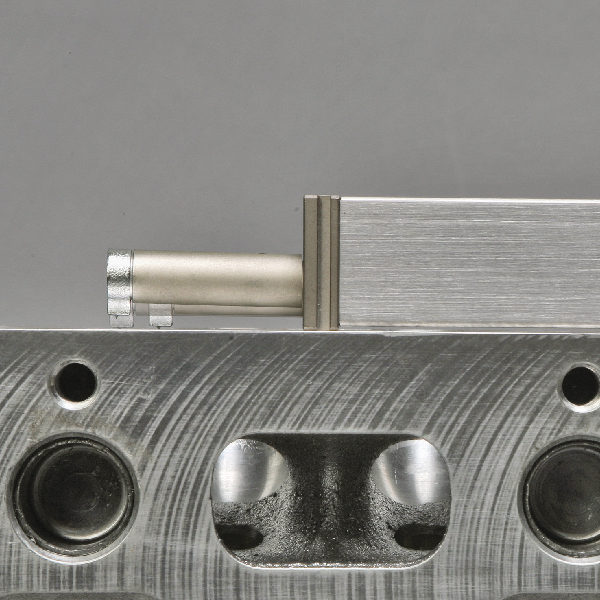

The SURFCOM 1400 works by using a precision stylus or sensor to trace the surface of a workpiece, detecting microscopic peaks and valleys. As the stylus moves across the surface at controlled speed and force, vertical displacements are converted into electrical signals. Advanced onboard electronics and software then analyze these signals to calculate surface roughness parameters (Ra, Rz, Rt, etc.) and, if equipped, 3D surface or contour features. The system supports automated multi-point measurements, AI-assisted setup, and compliance with international standards, providing fast, accurate, and repeatable surface characterization for quality control and inspection applications.

Locations We Serve

QS Metrology provides SURFCOM 1400 across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Authorized Supplier & Trusted Partner

Expert Product Consultation

Installation & On-Site Demonstration

Calibration, Training & Technical Support

After-Sales Service Across India

FAQs

It is used to measure surface roughness and texture accurately on machined and manufactured parts for quality assurance.

It provides standard roughness parameters such as Ra, Rz, Rt, Rq, and others in accordance with international standards.

Yes — it supports automated multi‑point measurement and reporting, reducing manual setup time and operator dependency.

Yes — it adheres to global roughness measurement standards including ISO, JIS, DIN, ASME, and CNOMO.

Yes — the system is expandable and upgradable for additional functions such as 3D surface analysis and contour measurement.

Yes — it includes advanced evaluation functions like film thickness and wear volume analysis for comprehensive surface characterization.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.