ZEISS SURFCOM NEX

The contour and surface measuring machines from ZEISS offer different, sometimes combinable sensors for roughness measurements, contour measurements or both.

SURFCOM NEX

The contour and surface measuring machines from ZEISS offer different, sometimes combinable sensors for roughness measurements, contour measurements or both.

Key Features of ZEISS SURFCOM NEX

Multi-Sensor Roughness & Contour Measurement

Modular & Future-Ready Design

Magnetic Linear Drive Technology

Optional CNC Automation

Large Granite Measuring Table Options

Find Metrology Solutions In Strategic Industrial Locations

- With two different sizes of granite measuring table and three different sizes of columns to choose from, ZEISS offers a wide range of solutions for various applications.

- Future-proof thanks to multi-sensor capability with optical and tactile sensors.

- All tactile styli are exchangeable without tools or screws.

- Space-saving DX variation suitable for production

- Solid, attractively-priced FX version with integrated active vibration damping or comprehensive SD desk furniture

- The optional CNC kit, consisting of linear and rotary positioning axis, allows higher productivity due to fully automatic measurements.

- Optional topography measurements (optical or contact)

How ZEISS SURFCOM NEX Work?

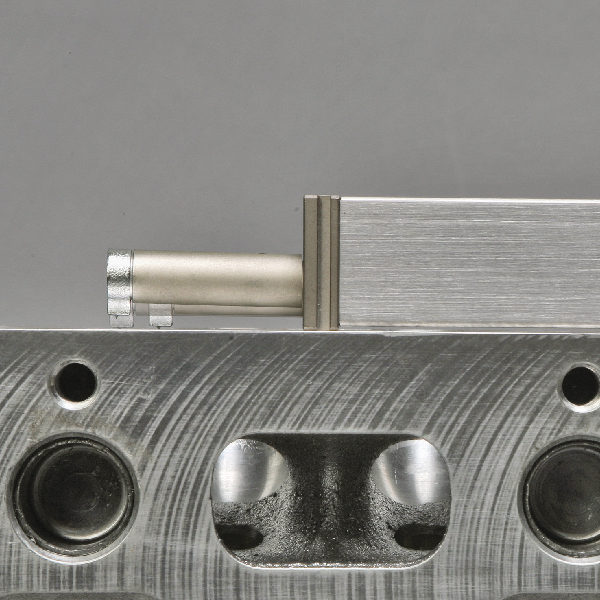

The ZEISS SURFCOM NEX measures surface roughness, contour, and topography using tactile and optical sensors. A diamond-tipped stylus detects surface peaks and valleys, while optical probes capture contours. The magnetic linear drive ensures smooth, vibration-free movement, and optional CNC automation allows fully automated measurements. Data is processed by advanced software to calculate roughness and geometric parameters, providing fast, precise, and versatile inspection for quality control.

Locations We Serve

QS Metrology provides ZEISS SURFCOM NEX across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Authorized Supplier & Trusted Partner

Expert Product Consultation

Installation & On-Site Demonstration

Calibration, Training & Technical Support

After-Sales Service Across India

FAQs

It is used for precise surface roughness, contour, and topography measurement of machined and precision parts.

It supports both tactile stylus measurement and optical sensing for versatile surface and shape analysis.

Yes — with the optional CNC automation kit, it can perform fully automated measurements with minimal operator intervention.

It can measure flat, curved, and complex contours, including grooves, profiles, and precision surfaces.

The magnetic linear drive delivers smooth, vibration‑free movement, improving measurement accuracy and repeatability.

Yes — it calculates roughness and contour parameters according to international standards (ISO, JIS, ASME) for quality assurance.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.