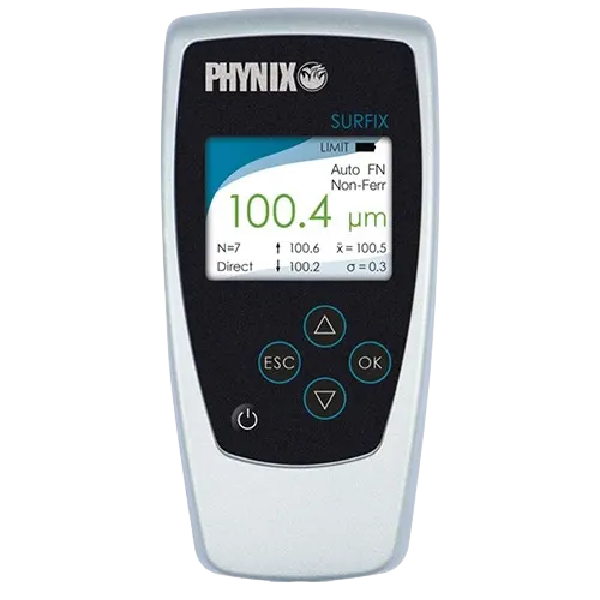

Surfix® SX Coating Thickness Gauge

Our Surfix® SX is a universal device and can be operated with various probes. Due to the our selection of interchangeable probes it offers a wide range of measurement applications.

Surfix® SX

Our Surfix® SX is a universal device and can be operated with various probes. Due to the our selection of interchangeable probes it offers a wide range of measurement applications. The option to store and transfer the measured data, the easy handling and the high accuracy make it the universal measurement gauge. The device is designed for tough operations in the field as well as in laboratories.

Key Features of Surfix® SX Coating Thickness Gauge

Dual Measurement Technology (Ferrous & Non‑Ferrous)

High‑Accuracy & Wide Measurement Range

User‑Friendly Digital Interface

Data Logging with USB/Bluetooth Connectivity

Interchangeable Probes for Versatility

Find Metrology Solutions In Strategic Industrial Locations

- Electroplating

- Paint shops

- Automotive industry

- Chemical industry

- Aerospace industry

- Ship building industry

- Research facilities and laboratories

- Detachable probe model

- Data memory of 2,000 readings

- Colour display

- Statistics

- USB interface

- Multiple probe options

- DIN, ISO, ASTM, BS standards

- IP 52 (protection against dust and dripping water)

| Range | 0 – 1500 μm (Depending on probe selected) |

| Min radius for convex surface | 1.5 mm |

| Min radius for concave surface | 5 mm |

| Min measuring area | 5 mm X 5 mm |

| Minimum Substrate Thickness | Ferrous – 0.2 mm Non-Ferrous – 50 μm (FN Model) |

| Standards | DIN, ISO, ASTM, BS |

| Calibration | Works calibration, zero calibration, one-foil calibration; zero-offset |

| Statistics | Number of measured values, mean value, standard deviation, minimum and maximum measured value |

| Memory | Max. 2000 readings |

| Data transfer | USB 2.0 interface |

| Display | Colour display |

| Protection Class | IP 52 (proof against dust and dripping water) |

| Dimensions | 137mm x 66mm x 23mm |

| Probe type | Detachable probe, Supports multple probes |

| Surface Temperature | -15 °C to 60 °C |

| Accuracy | Please refer supported probes |

| Resolution | Please refer supported probes |

| Warranty | 1 Years |

Supported Probes

| Range | 0 – 200 µm for Iron/Steel (FN & F models) 0 – 200 µm for Non-Ferrous metals (FN and N Models) |

| Substrate | Ferrous and Non-Ferrous |

| Tolerance | ± (0.7 µm + 1 % of reading) |

| Resolution | 0.1 µm or < 0.2 % of reading |

| Min. Area of measurement | 5 mm x 5 mm |

| Minimum radius of curvature | Convex 1.5 mm, Concave 5 mm |

| Minimum thickness of substrate | Iron/Steel: 0.2 mm Non-ferrous metals: 50 µm |

| Surface Temperature | -15 °C to 60 °C |

| Range | 0 – 1,500 µm for Iron/Steel (FN & F models) 0 – 1,500 µm for Non-Ferrous metals (FN and N Models) |

| Substrate | Ferrous (FN/F) and Non-Ferrous (FN/N) |

| Tolerance | ± (1 µm + 1 % of reading) |

| Resolution | 0.1 µm or < 0.2 % of reading |

| Min. Area of measurement | 5 mm x 5 mm |

| Minimum radius of curvature | Convex 1.5 mm, Concave 5 mm |

| Minimum thickness of substrate | Iron/Steel: 0.2 mm (FN and F Model) Non-ferrous metals: 50 µm (FN and N Model) |

| Surface Temperature | -15 °C to 60 °C |

| Minimum ID for measurement (for FN 1.5/90) | 12.5 mm |

| Range | 0 – 1,500 µm for Iron/Steel 0 – 1,500 µm for Non-Ferrous metals |

| Substrate | Ferrous and Non-Ferrous |

| Tolerance | ± (1 µm + 1 % of reading) |

| Resolution | 0.1 µm or < 0.2 % of reading |

| Min. Area of measurement | 5 mm x 5 mm |

| Minimum radius of curvature | Convex 1.5 mm, Concave 5 mm |

| Minimum thickness of substrate | Iron/Steel: 0.2 mm (FN and F Model) Non-ferrous metals: 50 µm (FN and N Model) |

| Surface Temperature | -15 °C to 60 °C |

| Minimum ID for measurement | 12.5 mm |

How Surfix® SX Coating Thickness Gauge Work?

The Surfix® SX Coating Thickness Gauge works by using non‑destructive dual measurement technologies to determine how thick a coating is on a substrate. When you place its interchangeable probe on a coated surface, the gauge measures changes caused by the coating layer using magnetic induction on ferrous substrates and eddy current on non‑ferrous substrates. These changes alter magnetic fields or induced currents between the probe and base material, and the gauge’s electronics convert that signal into a precise thickness value displayed on the screen. Built‑in data logging, statistics, and connectivity let you record, review, and transfer coating measurements easily for quality control, inspection, and reporting.

Locations We Serve

QS Metrology provides Surfix® SX Coating Thickness Gauge across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

High-Precision Measurement

Advanced Probe & Software Technology

Durable & Reliable Design

Wide Industry Applications

Expert Support & Service

FAQs

It is used for non‑destructive measurement of coating thickness on painted, plated, anodized, or protective surfaces.

It measures coatings on both ferrous (magnetic) and non‑ferrous (non‑magnetic) substrates using dual measurement technology.

It uses magnetic induction on ferrous metals and eddy current technology on non‑ferrous metals to calculate the coating layer thickness.

Yes — it supports data logging with USB and Bluetooth connectivity for easy export and reporting.

It can measure paint, powder coatings, plating, anodizing, and other surface layers over a wide thickness range.

Yes — it features a user‑friendly digital interface and intuitive operation suitable for shop‑floor and field applications.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables