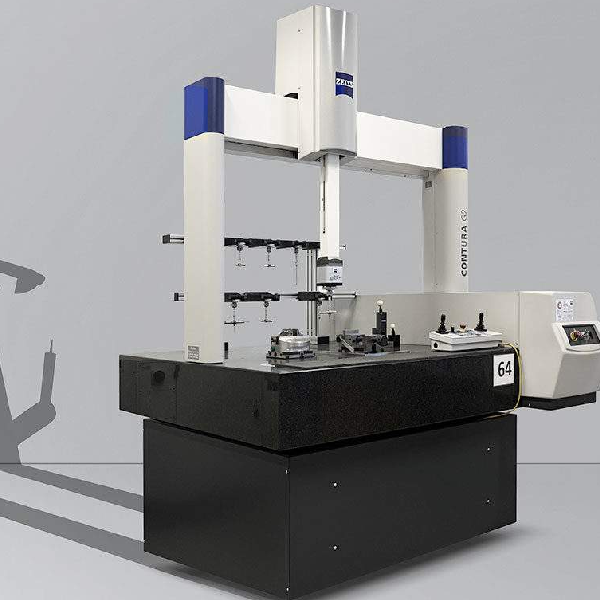

Zeiss CONTURA

The ZEISS CONTURA is a high-performance coordinate measuring machine (CMM) known for its precision, flexibility, and adaptability in quality assurance. It’s designed to handle diverse measurement tasks and is equipped with advanced features like multi-sensor technology, enabling it to seamlessly switch between tactile and optical sensors.

Key Features of Zeiss CMM CONTURA in India

High-Precision Measurement

Advanced Probe Technology

Intuitive Software

Robust & Durable Design

Wide Industry Applications

Find Metrology Solutions In Strategic Industrial Locations

Here's what makes the ZEISS CONTURA a versatile and efficient CMM

- MASS Technology: The ZEISS CONTURA utilizes a multi-application sensor system (MASS) that allows for easy switching between different sensor technologies, including tactile and optical probes.

- Wide range of probes: It supports various probe types, such as active and passive scanning probes, laser sensors, camera sensors, and white light sensors. This flexibility enables users to choose the optimal probe for each specific measurement task, from capturing fine grooves to inspecting large assemblies.

- 4-axis measurement (optional): With the addition of a rotary table, the CONTURA can perform optical measurements in 4 axes, enhancing its capabilities for inspecting complex geometries like gears and impellers.

- Reliable precision: ZEISS CONTURA achieves high measuring speed while maintaining reliable accuracy, ensuring consistent and repeatable results.

- Advanced compensation: Features like ZEISS VAST navigator, ZEISS VAST performance, and Computer-Aided Accuracy (CAA) dynamically compensate for stylus and machine deformation during high-speed scanning, further enhancing accuracy.

- Temperature stability: The HTG (High Temperature Gradient) option, incorporating floating glass-ceramic scales and temperature sensors, enables stable measurements even in larger temperature ranges (up to 26°C).

- Fast and efficient measurements: Navigator technology facilitates smooth, stop-and-go-free scanning, and the ProMax E automated probe changing magazine ensures efficient probe changes without impacting the measuring volume.

- Operator comfort: The CONTURA’s ergonomic design, including optimized height and width, ample legroom, and a movable control panel, ensures comfortable operation for users.

- Intuitive interface: The Zeiss CALYPSO software simplifies measurement programming and analysis with a user-friendly interface and graphical visualizations.

- Space-saving: The machine’s compact design allows it to fit into small measuring rooms while offering a generous measuring range, says ZEISS India.

- Industry 4.0 readiness: The CONTURA is equipped for Industry 4.0, offering digital services like ZEISS Smart Services for real-time performance monitoring and issue resolution.

- Energy efficiency: Features like ZEISS PowerSaver and ZEISS AirSaver minimize power and air consumption, contributing to a more sustainable measuring process.

- Adaptable to future needs: The modular design and optional sensor retrofitting ensure that the CONTURA can adapt to evolving measurement requirements and technological advancements.

In essence, the ZEISS CONTURA CMM offers a powerful combination of versatility, precision, ease of use, and future-proof design, making it an ideal choice for businesses seeking a comprehensive and reliable quality assurance solution

Reliable Zeiss CMM CONTURA in India

QS Metrology offers the Zeiss CMM CONTURA, a high-precision coordinate measuring machine designed for accurate, fast, and dependable dimensional inspection. Featuring advanced probe technology and intuitive software, it delivers precise measurements for complex components across diverse industries. Compact, durable, and user-friendly, the Zeiss CMM CONTURA ensures consistent, repeatable performance. Engineered to meet international standards, it is ideal for quality control, inspection, and precision engineering applications.

How Zeiss CMM CONTURA Work

The Zeiss CMM CONTURA measures the dimensions, geometry, and tolerances of components with high precision. Using advanced tactile and optical probes, it captures detailed points across a part’s surface. The data is processed by intuitive software, generating accurate 3D models, inspection reports, and deviation analyses. This ensures efficient quality verification, compliance with industry standards, and consistent, repeatable results.

Locations We Serve

QS Metrology provides Zeiss CMM CONTURA across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

High-Precision Measurement

Advanced Probe & Software Technology

Durable & Reliable Design

Wide Industry Applications

Expert Support & Service

FAQs

The Zeiss CMM CONTURA is a high-precision coordinate measuring machine designed to measure dimensions, geometry, and tolerances of components with accuracy and reliability.

It uses advanced tactile and optical probe technology to capture detailed measurement points on a part’s surface. The data is processed by intuitive software to create 3D models, inspection reports, and deviation analyses.

It is widely used in automotive, aerospace, medical devices, precision engineering, and other industries requiring high-accuracy dimensional inspection.

It provides micron-level accuracy, repeatable measurements, multi-sensor support, efficient inspection, and detailed reporting for quality control and compliance.

Yes, it features user-friendly software, automated measurement functions, and intuitive controls suitable for both experienced metrologists and new operators.

Yes, QS Metrology offers professional installation, calibration, operator training, and reliable after-sales support to ensure optimal performance and long-term reliability.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables