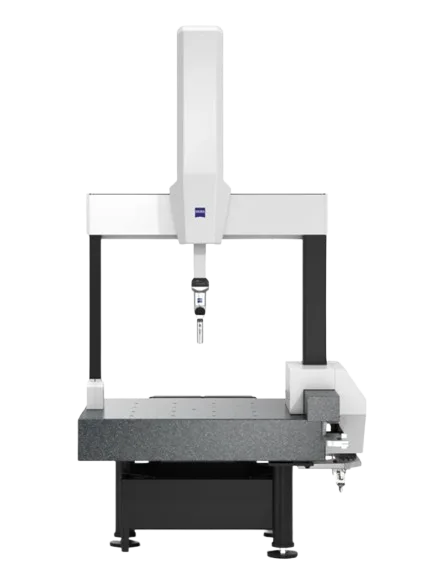

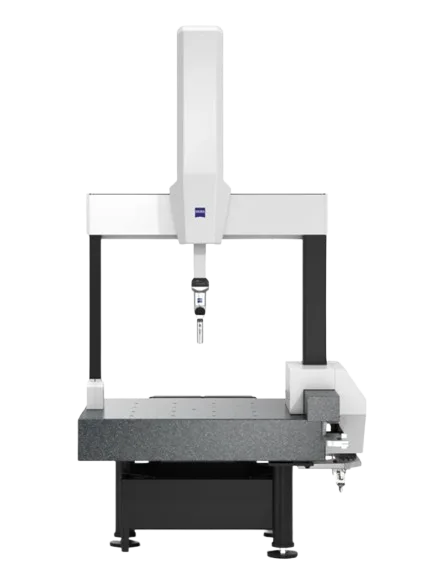

Zeiss SPECTRUM

The ZEISS SPECTRUM is a family of bridge-type coordinate measuring machines (CMMs) designed for high-precision measurement tasks in various industries. It’s engineered to be both stable and flexible, offering a compelling price-performance ratio.

Key Features of Zeiss CMM SPECTRUM

High-Precision Measurement

Advanced Probe Technology

User-Friendly Software

Robust & Durable Design

Wide Application Range

Find Metrology Solutions In Strategic Industrial Locations

- Scanning Capabilities: ZEISS SPECTRUM is unique in its class for combining both tactile and optical scanning functionalities. It supports tactile scanning with various sensors, including the VAST XXT TL3 compact design sensor and the VAST XT gold sensor for active scanning. The integration of the LineScan One laser scanner enables high-speed optical measurements.

- Accuracy & Flexibility: The machines deliver high accuracy values, with the ZEISS SPECTRUM verity model achieving an accuracy of up to 1.7+L/300 µm. The RDS probe carrier allows for flexible angle positioning, up to 20,736 positions for the SPECTRUM verity model, ensuring adaptability across diverse applications.

- Efficiency: Features like the ZEISS SoftTouch Mode with the VAST XXT TL1 sensor, specifically designed for flexible parts, can reduce measurement cycle times by up to 40%.

- Design & Technology: The ZEISS SPECTRUM boasts a compact footprint of 2.2 m², optimizing lab space utilization. It incorporates glass ceramic scales for thermal stability and a stiff base frame for enhanced reliability and earthquake protection. The ZEISS CALYPSO software provides a user-friendly interface for programming inspection plans and automated measurement execution

ZEISS SPECTRUM finds applications in a wide range of industries including:

- Industrial Manufacturing: Measuring CNC parts, housings, and mechanical components.

- Electronics: Inspecting connectors, housings, middle frames, and thin foils.

- Automotive: Suitable for small housings, stamped parts, CNC-machined parts, and plastic parts.

- Job Workshops: Ideal for measuring manufacturing, sheet metal, stamping, and plastic parts

ZEISS SPECTRUM is a powerful and versatile CMM offering high accuracy, advanced scanning capabilities, and efficient operation, making it a valuable tool for quality control in various manufacturing and industrial settings.

Trusted Zeiss CMM SPECTRUM in India

QS Metrology offers the Zeiss CMM SPECTRUM, a high-precision coordinate measuring machine designed for accurate, fast, and reliable dimensional inspection. Equipped with advanced probe technology and intuitive software, it allows precise measurement of complex components across multiple industries. Compact, durable, and easy to operate, the Zeiss CMM SPECTRUM ensures consistent, repeatable, and dependable performance. Engineered to meet international standards, it is ideal for quality control, inspection, and precision engineering applications.

How Zeiss CMM SPECTRUM Works

The Zeiss CMM SPECTRUM measures the precise dimensions, geometry, and tolerances of components with high accuracy. Using advanced tactile and optical probe technology, the system captures detailed measurement points across a part’s surface. The data is processed by intuitive software, generating precise 3D models, inspection reports, and deviation analyses. This enables operators to verify component quality, maintain strict manufacturing standards, and ensure compliance with industry specifications efficiently and reliably.

Locations We Serve

QS Metrology provides Zeiss CMM SPECTRUM across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

High-Precision Measurement

Advanced Probe & Software Technology

Durable & Reliable Design

Wide Industry Applications

Expert Support & Service

FAQs

The Zeiss CMM SPECTRUM is a high-precision coordinate measuring machine designed to inspect and measure the dimensions, geometry, and tolerances of complex components.

It uses advanced tactile and optical probes to capture measurement points on a part’s surface. The data is processed by intuitive software to generate accurate 3D models, inspection reports, and deviation analyses.

It is widely used in automotive, aerospace, medical devices, precision engineering, and other manufacturing industries requiring high-accuracy inspection.

It offers micron-level accuracy, repeatable measurements, multi-sensor support, efficient inspection processes, and detailed reporting for quality control and compliance.

Yes, the system features user-friendly software and automated measurement functions, making it accessible for both experienced metrologists and new operators.

Yes, QS Metrology offers professional installation, calibration, operator training, and reliable after-sales support to ensure optimal performance and long-term reliability.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables