In modern manufacturing, where every micron matters, the shape and accuracy of a component’s surface profile can directly affect its performance, fit, and longevity. This is where a contour measurement machine becomes indispensable. From automotive parts to aerospace components, maintaining precision in contours and profiles ensures reliability and quality.

This comprehensive guide explains what a contour machine is, how it works, and why it has become one of the most essential tools in the field of metrology and precision measurement equipment.

What is a Contour Measurement Machine?

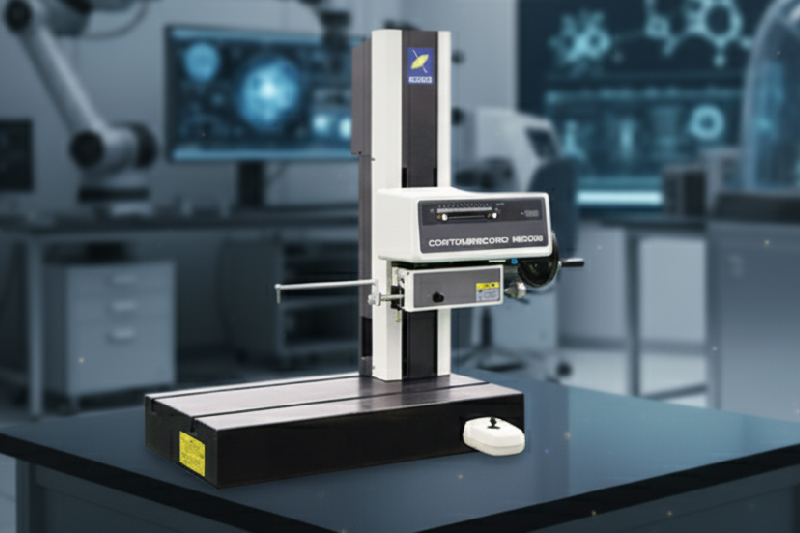

A contour measurement machine, often called a contour measuring instrument or surface contour measurement system, is designed to measure and evaluate the profile or contour of a workpiece surface. In simple terms, it captures the shape of a component’s surface — including angles, radii, grooves, and curves — and compares it against design specifications.

Unlike surface roughness testers that focus on micro-level texture, contour machines assess the macro geometry or form and contour measurement of parts. They help determine whether a component’s physical shape aligns with the intended design model, which is critical for assemblies requiring perfect fits.

Working Principle of Contour Measurement Machines

The working of a contour machine is based on stylus-based or optical scanning technology. The stylus tip traces the surface of the component along a defined path, capturing vertical (Z-axis) and horizontal (X-axis) displacements. These measurements are then converted into a contour profile using specialized software.

Key steps in contour machining process –

- Component Placement – The part is mounted securely on the measuring table using fixtures to prevent vibration or displacement during measurement.

- Stylus Movement – A fine stylus or probe moves along the surface. Any variation in the surface height is detected as displacement, which is recorded digitally.

- Data Acquisition – The system collects continuous data points corresponding to the surface profile. In advanced machines, this data is captured at extremely high resolution.

- Profile Analysis – The software reconstructs the contour and compares it to CAD or reference data. Engineers can analyze dimensions such as radius, angle, depth, and slope.

- Reporting – A detailed inspection report is generated showing deviations from the nominal profile, enabling corrective actions in machining or design.

Types of Contour Measurement Systems

There are several types of surface contour measurement systems used in industrial metrology –

- Stylus-based Contour Machines – The most common and cost-effective, ideal for mechanical contact measurement with high accuracy.

- Optical or Non-Contact Systems – Use lasers or white-light interferometry for non-contact measurement, suitable for delicate or soft surfaces.

- Hybrid Systems – Combine contour and roughness measurement in one unit, offering dual functionality for comprehensive surface inspection.

Applications in Modern Manufacturing

Contour measurement plays a critical role in various industries where dimensional accuracy defines product performance.

- Automotive Industry – Contour machines are used to inspect engine components, camshafts, crankshafts, gears, and seals. Accurate form and contour measurement ensures smoother operations and longer life of mechanical parts.

- Aerospace and Defense – In aircraft manufacturing, even a minor deviation in contour can lead to aerodynamic inefficiency. Contour measurement in metrology helps maintain strict tolerance levels in turbine blades, fuselage structures, and precision fittings.

- Tool and Die Industry – Die and mould manufacturing demands flawless profiles. Contour machining verifies tool geometry to ensure perfect replication during production.

- Medical and Surgical Equipment – Medical implants and surgical tools require ultra-precise profiles for safety and performance. A contour measuring instrument ensures these parts meet international quality standards.

- Electronics and Micro-Components – Miniaturized components in electronics rely on precision measurement equipment to maintain accuracy in contours that impact electrical connectivity and assembly.

Advantages of Using Contour Measurement Machines

- High Precision and Repeatability – Delivers sub-micron accuracy in profile measurement.

- Time-Efficient Inspection – Automated scanning reduces inspection time compared to manual measurement methods.

- Data Traceability – Digital records allow easy traceability and documentation for audits.

- Improved Product Quality – Ensures every part meets design intent, minimizing rework and rejections.

- Integration with Smart Manufacturing – Modern systems support data connectivity for real-time quality monitoring.

Why Quality Engineers Rely on Contour Machines?

Quality engineers use contour machines not only to check product conformance but also to identify process inefficiencies. By studying the contour profile, they can detect tool wear, thermal distortion, or improper machining parameters early in the production line. This leads to preventive corrections and improved consistency across batches.

Additionally, the adoption of contour machining data in design validation bridges the gap between R&D and production. Engineers can compare prototype data with design files to ensure manufacturability and compliance with standards.

Maintenance and Calibration Tips

To achieve consistent results, periodic calibration of the contour measurement machine is essential. Regular cleaning of the stylus tip, alignment verification, and environmental control (temperature, vibration) help maintain system accuracy. Using certified reference standards further strengthens reliability in inspection results.

Future Trends in Contour Measurement

The evolution of form and contour measurement is heading toward automation and non-contact solutions. Artificial intelligence and machine learning are being incorporated to analyze complex profiles faster. As manufacturing precision tightens, the demand for integrated surface contour measurement systems will continue to grow across industries.

A contour measurement machine is more than just an inspection tool—it’s a cornerstone of precision engineering. Whether it’s improving part accuracy, ensuring functional fit, or validating manufacturing processes, contour measuring instruments provide engineers with the insight needed to deliver perfection.

For industries that prioritize precision, adopting advanced contour machines and contour machining practices ensures long-term quality, reliability, and competitive advantage.