HandySurf+ Portable Surface Roughness Tester

HandySurf+ is a simple solution to measure, evaluate and document surface roughness – from incoming goods to production all the way to final inspection.

HandySurf+ - Portable Surface Roughness Tester

The Carl Zeiss HANDYSURF+ is a range of portable surface roughness testers designed for inspecting surface finish in various stages of production, including incoming goods, manufacturing, and final inspection. These instruments are built for versatility and ease of use, making them suitable for a wide range of industries such as automotive, mechanical engineering, and medical technology.

Key Features of HandySurf+ - Portable Surface Roughness Tester

Portable & Flexible Surface Measurement

High Resolution & Wide Measuring Range

User-Friendly Interface with Color Display

Standards-Compliant Roughness Analysis

Data Storage & Connectivity Options

Find Metrology Solutions In Strategic Industrial Locations

Surface Roughness Tester in Punjab

Surface Roughness Tester in Himachal Pradesh

Surface Roughness Tester in Uttarakhand

- Portability and Flexibility: HANDYSURF+ instruments are compact and lightweight, designed to be easily carried to the workpiece for measurement in various orientations (horizontal, vertical, overhead). They can operate on rechargeable batteries, offering independence from a power source.

- Ease of Use: The devices feature a user-friendly interface, often including a color LCD screen, and intuitive controls for straightforward operation, even for users without extensive measurement expertise. An automatic function simplifies measurement by setting parameters like range, path, and cut-off based on the surface being measured.

- High Resolution and Wide Measuring Range: HANDYSURF+ models offer a wide measuring range of 370 µm and a high resolution of 0.0007 µm, enabling accurate and detailed surface analysis.

- Compliance with Standards: These instruments adhere to common surface standards, including ISO, DIN, CNOMO, ASME, and JIS.

- Data Handling and Analysis: HANDYSURF devices allow for storing measurement results and conditions in internal memory or on external USB drives. They can be connected to a PC for data transfer and further analysis, and also support connection to a compact printer for on-site documentation. The HANDYSURF+ offers graphical representation of measurements for on-site verification and includes advanced analysis functions like BAC, ADC, peak count, and motif analysis.

- Interchangeable Styli: A variety of styli are available and easily interchangeable to suit different measurement applications, including deep bores, small holes, and rounded surfaces

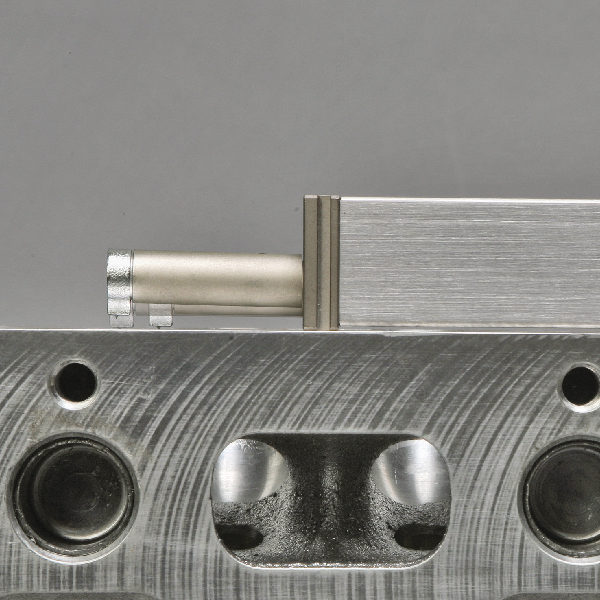

The HANDYSURF+ series is available in three models: 35, 40, and 45. They differ in their features, such as the standard type (35), the retract-type (40) for automatic probe arm raising and lowering, and the transverse trace-type (45) for measuring in narrow areas like crankshaft pins.

Zeiss HANDYSURF offers a portable, accurate, and user-friendly solution for surface roughness measurement and analysis across various industrial applications

Z direction | -210 to +160 μm (370 μm) |

X direction | 16 mm |

Evaluation Length | 0.2 to 16 mm |

Measurement Speed | 0.5, 0.6, 0.75, 1.0 mm/s |

Pickup Sensing type | Differential inductance |

Measurement Method | Skid |

Z direction resolution | 0.0007 μm/-210 to +160 μm |

Measurement force | 4 mN |

Stylus Radius | rtip = 5 μm |

Stylus Angle | 90°cone |

Stylus Material | Diamond |

Calculation Standards | Comply with JIS2013/2001, JIS1994, JIS1982, ISO1997/2009, ISO13565, DIN1990, ASME2002/2009, ASME1995, CNOMO |

Parameter – Profile Curve | Pt, Rmax, Rz, Rk, Rpk, Rvk, Mr1, Mr2, Vo, K, tp |

Parameter – Roughness Curve | Ra, Rq, Rz, Rv, Rc, Rt, RSm, RΔq, Rsk, Rku, Rmr(c), Rmr, Rδc, Rz94, R3z, RΔa, Ry, Sm, S, tp, PC, RPc JIS, RPc ISO, RPc EN, Pc, PPI, Rp, Rmax, Mr1, Mr2, Rpk, Rvk, Rk, Vo, K, A1, A2, Rpm, Δa, Δq, Htp |

Parameter – Motif | R, Rx, AR, W, Wx, AW, Rke, Rpke, Rvke, NCRX, NR, CPM, SR, SAR, Wte, NW, SAW, SW, Mr1e, Mr2e, Vo, K |

Evaluation Curve | Profile Curve, Roughness Curve, ISO13565Special Roughness Curve, Roughness motif curve, Waviness motif curve, Upper envelope waviness curve |

Characteristics graph | Bearing area curve, Amplitude distribution curve |

Filter type | Gaussian, 2RC (phase compensation), 2RC (non-phase compensation) |

Cutoff value – λc | 0.08, 0.25, 0.8, 2.5 mm |

Cutoff value – λs | None, 2.5, 8 μm |

Display | 2.4-inch color liquid crystal panel |

Data output | USB connectors for USB memory/printer connection x 1, Micro USB connector for USB communication x 1 |

Print output | Optional (external printer unit) / Thermal recording paper width: 58 mm (recording width: 48 mm) |

Language | Japanese, English, Chinese (Traditional Chinese/Simplified Chinese), Korean, Thai, Malay, Vietnamese, Indonesian, German, French, Italian, Czech, Polish, Hungarian, Turkish, Swedish, Dutch, Spanish, Portuguese |

Power Supply | AC100 to 240 V ±10%, 50/60 Hz, Single phase (Included AC adapter) |

Power Supply – Charging | Built-in battery (to be charged using AC adaptor, PC USB port, USB battery), charging period: 4 hours (about 1000 measurements can be take when fully charged) |

Power consumption | Maximum 10 W |

External dimensions | Amplification indicator: 184.5 x 68 x 57.4 mm/about 500 g for the entire system |

How HandySurf+ Portable Surface Roughness Tester Work?

The HandySurf+ Portable Surface Roughness Tester uses a precision stylus contact method to measure surface texture. A diamond-tipped stylus traces across the surface of a part at a controlled speed, and microscopic vertical movements of the stylus as it moves over peaks and valleys are detected by a high-resolution sensor. This movement is converted into an electrical signal and processed by the device’s electronics to calculate surface roughness parameters such as Ra, Rz, and others according to international standards (ISO, DIN, ASME, JIS). The instrument displays these values and a graphical profile on the screen, and results can be stored or transferred via USB for reporting. HandySurf+ combines portable, on-site measurement flexibility with accurate roughness analysis for quality control in production and inspection environments.

Locations We Serve

QS Metrology provides HandySurf+ Portable Surface Roughness Tester across India, serving all major industrial regions, including:

Delhi NCR, Rajasthan, Punjab, Uttar Pradesh, Himachal Pradesh, Uttarakhand, Jammu & Kashmir

Why Choose QS Metrology?

Authorized Supplier & Trusted Partner

Expert Product Consultation

Installation & On-Site Demonstration

Calibration, Training & Technical Support

After-Sales Service Across India

FAQs

It is used to measure and evaluate surface texture/roughness of parts directly on the production floor or in inspection labs.

HandySurf+ can measure key parameters like Ra, Rz, Rt, Rq and many others with graphical waveform and profile analysis.

It is compact and handheld, designed for measuring in horizontal, vertical, and overhead positions, and can be used on-site at the workpiece.

It complies with major international standards including ISO, DIN, CNOMO, ASME and JIS for roughness measurement.

Yes — it supports USB connection to PCs, printers, or flash drives for storing data and transferring measurement results.

Yes — it offers graphical representations of measurement results and advanced analysis options like BAC, ADC, peak counts, and motif analysis.

Industries We Serve

Automotive

Medical Device & Pharmaceutical

Aerospace

Electronic & Electric Component

Chemicals & Petrochemicals

Metal Foundries & Casting

Energy, Power & Renewables

Mining & Minerals

Looking for a Custom Measurement Solution?

Our experts will guide you to the right technology.