Blog

In today’s fast-paced manufacturing and metal fabrication industries, quality control is no longer just a final checkpoint—it is an ongoing process that …

In today’s precision-driven manufacturing world, quality control isn’t just a checkpoint — it’s the foundation of every successful production process. Companies in …

In industries where surface protection, durability, and quality control are critical, accurate coating measurement plays a vital role. Whether it is paint, …

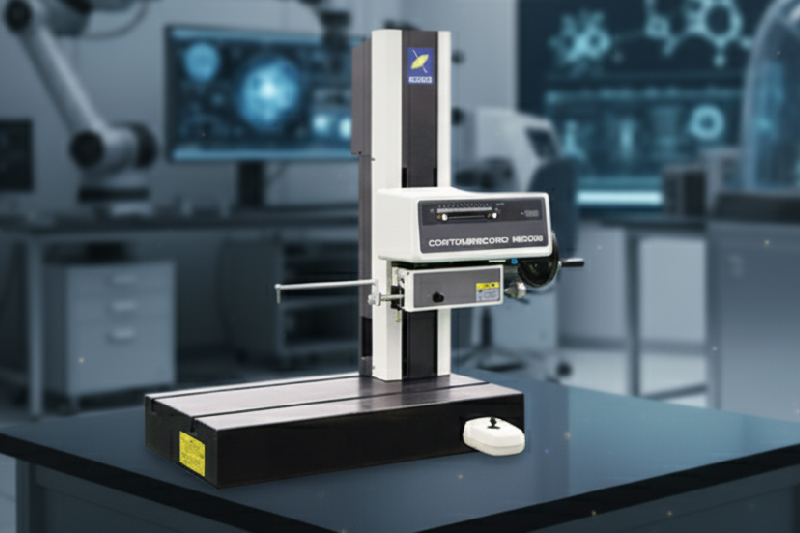

In modern manufacturing and quality control, surface roughness measurement plays a critical role in ensuring product performance, durability, and compliance with international …

In modern metrology and material testing environments, handheld XRF analyzers have become indispensable tools for rapid, non-destructive elemental analysis. From positive material …

In modern metrology and material testing, speed, accuracy, and non-destructive analysis are critical. One technique that has become indispensable across industries is …

Accurate material identification and elemental composition analysis are fundamental requirements in modern material science. From quality assurance and failure analysis to regulatory …

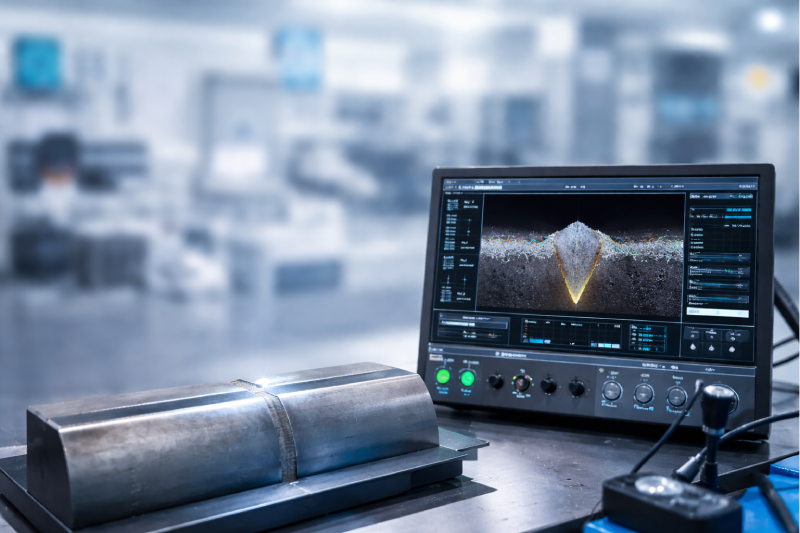

In modern manufacturing, welding quality is no longer judged by appearance alone. Industries that demand precision, safety, and compliance rely heavily on …

In modern manufacturing, even the smallest surface imperfections can affect performance, durability, and product quality. From automotive components and aerospace parts to …

In today’s precision-driven manufacturing environment, accurate measurement is not optional—it’s essential. From automotive components to high-precision industrial parts, quality control depends heavily …

In today’s precision-driven manufacturing environment, even the smallest surface variation can significantly impact product performance, reliability, and lifespan. Surface roughness and contour …

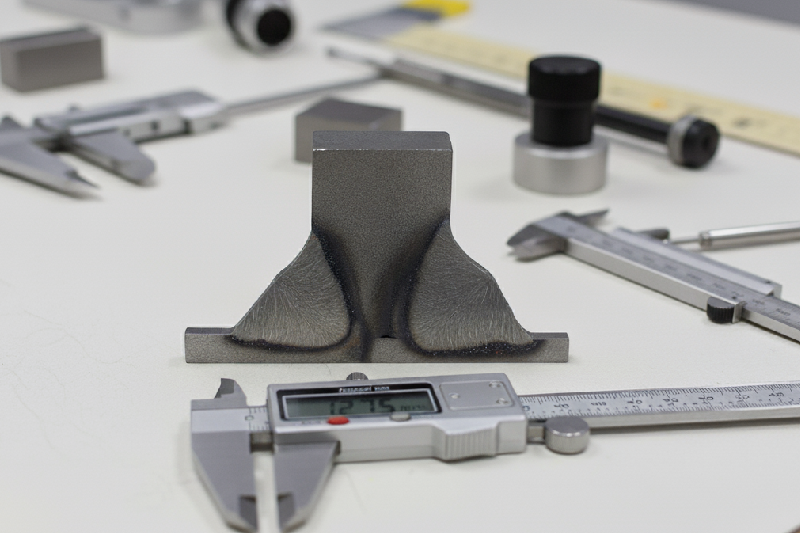

Precision measurement is the backbone of modern manufacturing. From automotive and aerospace components to medical devices and precision engineering parts, even the …

In modern manufacturing, precision is no longer an option — it is a necessity. Whether you are producing automotive components, machined parts, …

In every industry where metal parts, structures, or finished products are coated, the quality of that coating determines the durability, appearance and …

In the automotive industry, the quality of paint and coating directly affects durability, corrosion resistance, and the overall appearance of a vehicle. …

In today’s precision-driven manufacturing landscape, engineers rely on advanced tools to maintain product quality, improve efficiency, and reduce errors. Among the many …

What is a Metallurgical Microscope? A metallurgical microscope is a high-precision optical instrument designed for observing and analyzing the structure of metals …

In modern manufacturing and quality control, precision and clarity are everything. Engineers and quality professionals need to visualize even the smallest surface …

In every manufacturing or fabrication process, welding plays a crucial role in ensuring the strength and durability of a product. From automotive …

In today’s competitive manufacturing environment, precision and reliability are everything. Industries like automotive, aerospace, and foundries depend heavily on accurate inspection systems …

In today’s era of precision manufacturing, accuracy and consistency are non-negotiable. Every component, whether used in automotive, aerospace, or medical industries, must …

In modern manufacturing, where every micron matters, the shape and accuracy of a component’s surface profile can directly affect its performance, fit, …

Understanding Surface Roughness Measurement Surface roughness measurement plays a crucial role in quality control and precision engineering. It helps determine the texture …

X Ray Fluorescence (XRF) is a reliable and non-destructive method used to find out what elements are present in a material. It …

In modern industries where precision, safety, and compliance are essential, Positive Material Identification (PMI) plays a critical role. The PMI machine is …

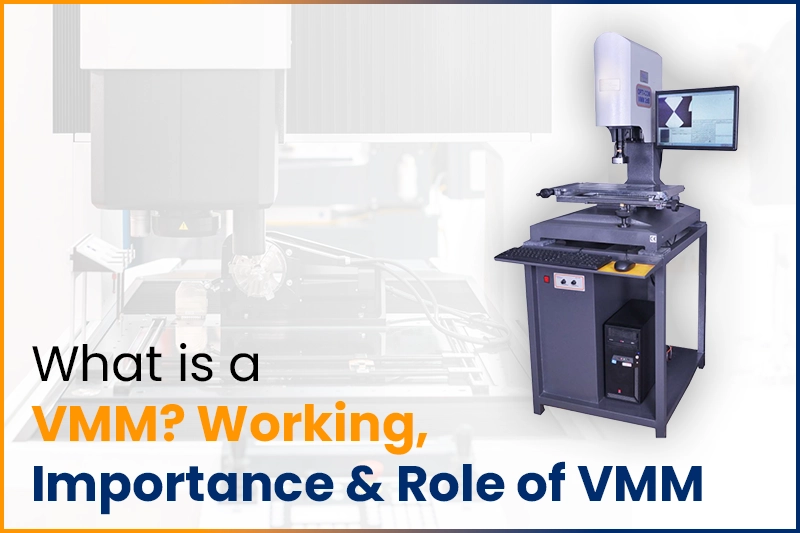

A Video Measuring Machine (VMM), also known as a Vision Measurement Machine, is an advanced non-contact measuring system used for capturing precise …

A coating thickness gauge is a precision instrument used to measure the thickness of coatings applied to different surfaces. Also called a …

What Is a CMM Machine? A CMM (Coordinate Measuring Machine) machine is a high-precision device used 3D inspection of parts. Using a …

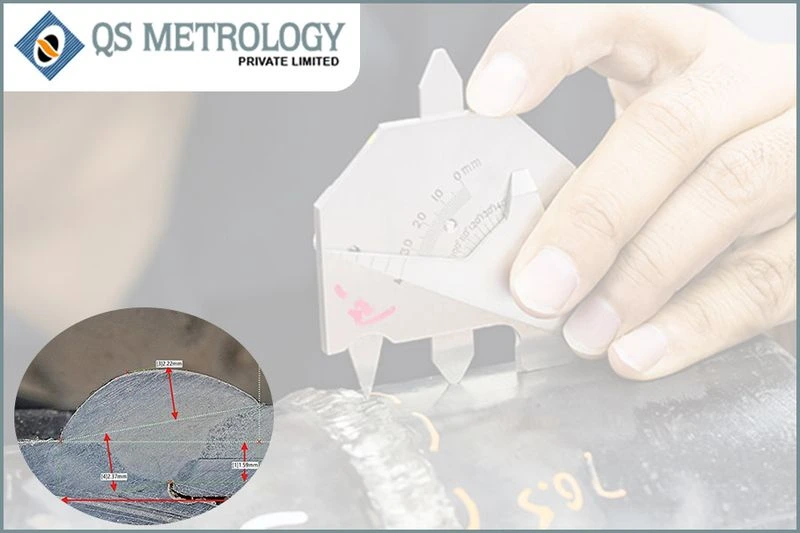

Weld penetration defects and streamlining of measurement and inspectionIf you are into metal joining business, you know the importance of welding. This …

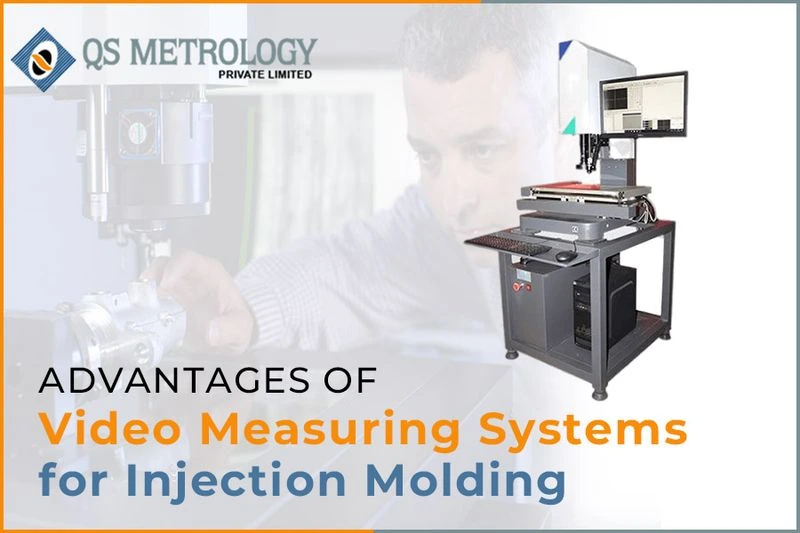

Advantages Of Video Measuring Systems For Injection Molding The video centric vision system for precision inspection and measurement is one flexible and …